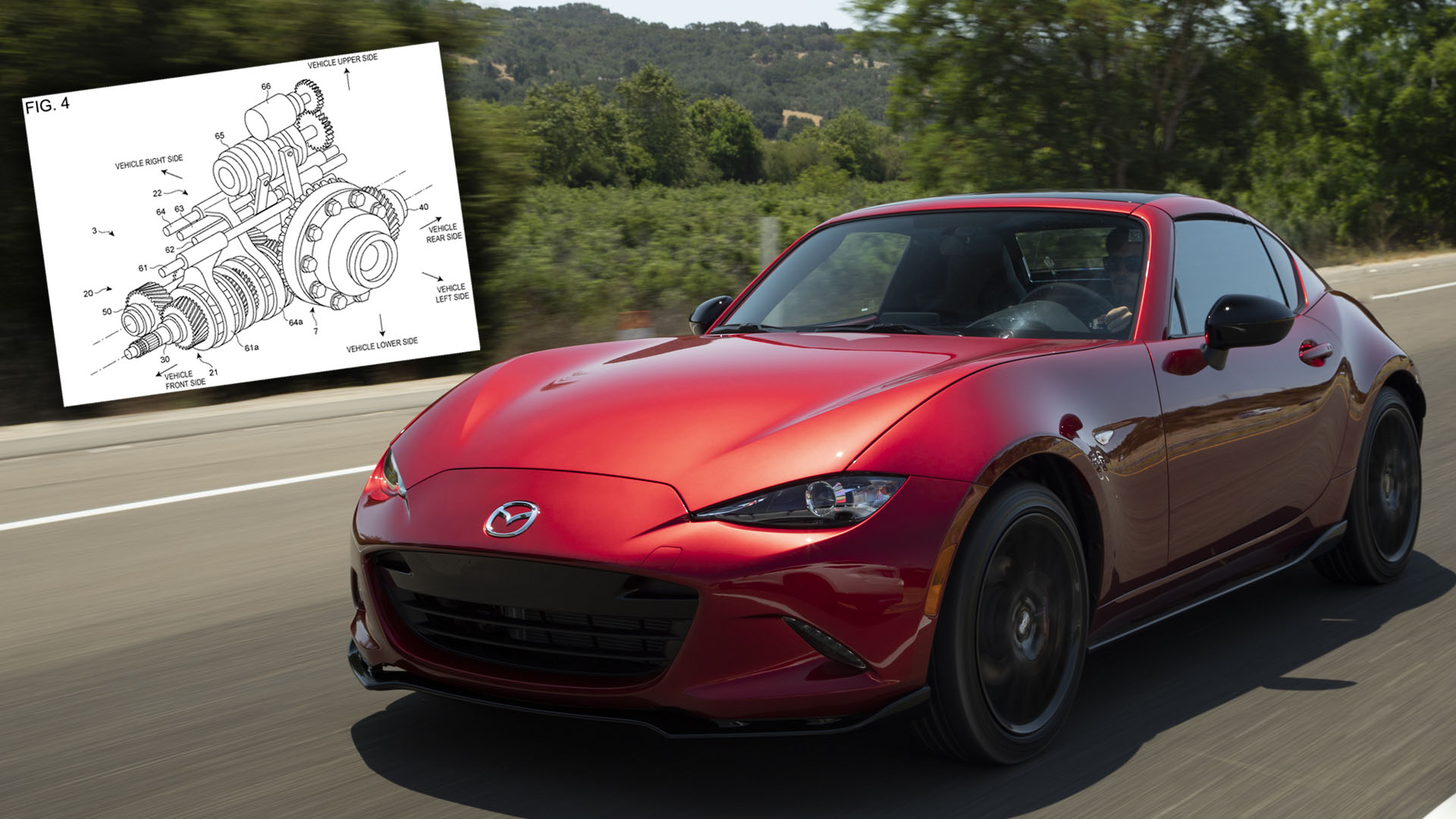

About a month ago we covered an eye-opening (and surprisingly detailed) patent from Mazda, wherein the company laid out what it claimed to be a lightweight hybrid drivetrain intended for a future compact sports car. It’s rare to see specific models get associated with technology patents, but the writing was clearly on the wall this time: the next Mazda Miata could potentially go a lot more high-tech. Now, a new patent published earlier this month by Mazda expands on that even further.

In short, it’s a rear-mounted transaxle, just like the one described in the earlier patent. There are quite a few interesting things to unpack about it beyond just the basic specs, though. It is, for all intents and purposes, an automatically shifted six-speed manual transmission, i.e a sequential gearbox. Let me be clear when I say that, though: It is a single-clutch manual transmission in terms of its design. It does, however, have a mechanism to automatically change gears.

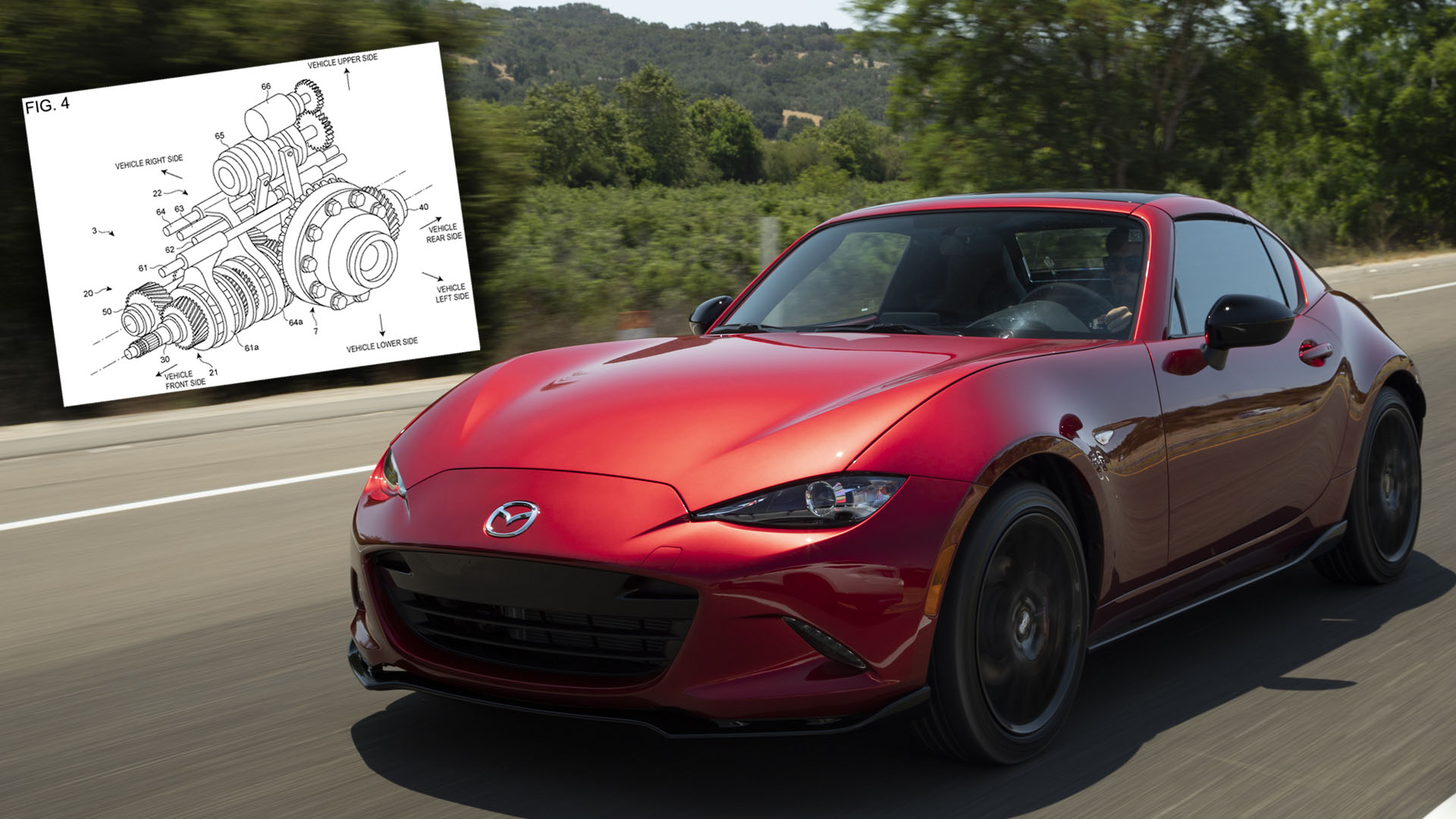

This patent, like the previous Mazda document referencing this transmission, goes into a high level of detail describing it, especially when it comes to the illustrations:

Those familiar with sequential transmissions will have spotted the barrel cam already. Labeled “65” in the illustration above, it’s the heart of the mechanism that changes the gears in the transmission. When it rotates, shift forks with dowel pins jutting into the grooves cut into its round surface are forced forwards or backward in a particular pattern, selecting any number of the six forward gears. We’ve actually covered an excellent video on a 3D-printed version of this sort of transmission, which helps clarify how the whole system works. It’s important to note that the system in the linked video uses a shift mechanism that this unit is not equipped with.

For reference, lots of transmissions work this way. They are, for instance, particularly popular in motorcycles. They aren’t popular in more mainstream vehicles sold in the United States, and it’s important to know why. Sequential transmissions like this are lightweight, inexpensive, and known for shifting hard. That’s a good thing in high-performance or racing applications—Formula 1 cars use highly-developed sequential transmissions—but not so desirable for the average commuter.

Importantly, the unit works the same way as a manual transmission, but the gear selection mechanism is just different. That means turning this transmission into a manual could be as simple as swapping out a modular group of components located on top of the transmission case, and adding a few more parts to get it all working with a conventional H-pattern shifter. In fact, Mazda says as much in a very engineer-y sort of way: “In the present embodiment, the transmission is used which causes the shift rods to be operated to move by the actuator on the basis of a manual transmission, but the transmission is similarly applicable to a manual transmission.”

In other words, they’re very similar and it wouldn’t be too hard to change them out. That looks particularly easy this time around because the barrel cam is likely driven by an electric motor. A shifter in the cabin or paddle shifters will simply send an electrical signal to the motor telling it to be in a certain position, which will change the position of the shift forks in short order. The document notes hydraulics could be used to change gears as well.

The differential, as with other transaxles, is mounted inside the transmission case as an integral part of the gearbox. It’s located on the driver’s side of the vehicle with the axle shaft running between the shift rods and the transmission gears themselves. In many other cases, the transmission portion of the transaxle is mounted ahead or behind the differential, but that’s not the case here. Mazda uses a third countershaft, labeled “23” in the drawing above, to send power to the diff located smack dab in the middle of the transaxle when you look at it lengthwise. As far as I am aware, this is not a very common design at all, and you can see why. There’s not a lot of space to run an axle shaft through the center of a transmission.

This unconventional design, the patent explains, is primarily to save space. For some context, the original Mazda patent we covered last week said using a transaxle in the first place was to make more room for the occupants, so in addition to going with an overall layout to add to the cabin volume, they’re also utilizing a compact design for the transaxle itself to further boost the savings. Just the same, the document says this layout is better for “operational stability,” aka handling. It’s all very Mazda.

For those still uncertain about the exact connection between this and the former patent, it’s to be noted that this document references the fact that this transaxle could be used in a “four-wheel-drive” context. It mentions this as background in a very roundabout sort of way, and indeed the connection I’m drawing could be considered speculative, but it’s still there in my opinion. The text states that in a layout like this you can achieve four-wheel drive. However, assumedly since this transaxle is not something that can be modified to easily accommodate a forward-facing output shaft (in order to use a conventional transfer case,) you would need a whole other transmission mounted ahead of the transaxle to achieve this. Specifically, it references a Japanese patent where a “continuously variable transmission arranged in a vehicle-body front portion and on a vehicle rear side of a starting clutch,” is used to achieve this.

Now on the face of it, this translates into Mazda having a compact lightweight sports car with two transmissions, one of which is a CVT mounted behind the clutch but ahead of the rear transaxle which somehow sends power to the front wheels. I think the term “continuously variable transmission” is being used loosely here, though. This statement is more likely than not referring to the 25 kW (33.5-horsepower) electric motor referenced in the previous patent—labeled “16” in the schematic below—from last month, which is described to be in the same location this “CVT” would be. And technically, an electric motor in a hybrid car, especially one combined with some kind of reduction drivetrain as most are, is a continuously variable way to transmit power. This is, of course, speculative. But I think it’s informed speculation.

So, as usual with some of these patents, they have broad implications but unstated precise applications. Will this end up in the Miata, which feels like a safe assumption when we hear “compact sports car,” or another type of Mazda? That’s unclear. What is clear, though, is that this is a highly-developed, unique transaxle that could be used in an “automatic,” rear-wheel-drive compact car to jive nicely with a hybrid system, or in a much simpler manual one with a few modifications. It’s also clear that this is very exciting, and if it ends up in a production car, it’s absolutely one an enthusiast would want to drive.

A Miata with a six-speed transaxle and a high-performance hybrid system? As long as the weight stays down, it sounds like a good time.

Got a tip or question for the author? You can reach them here: peter@thedrive.com