Stellantis is one of many automakers that’s vocal about keeping its internal combustion business going strong, but the writing is on the wall. As industry leaders have noted recently, costs have to come down, cars need to be more profitable, and parts need to be simpler to compete with electric vehicles. A new patent published by Stellantis recently takes this concept to extremes.

The automaker apparently plans to do more than cast exhaust manifolds into cylinder heads as some others have—it wants to integrate entire turbochargers.

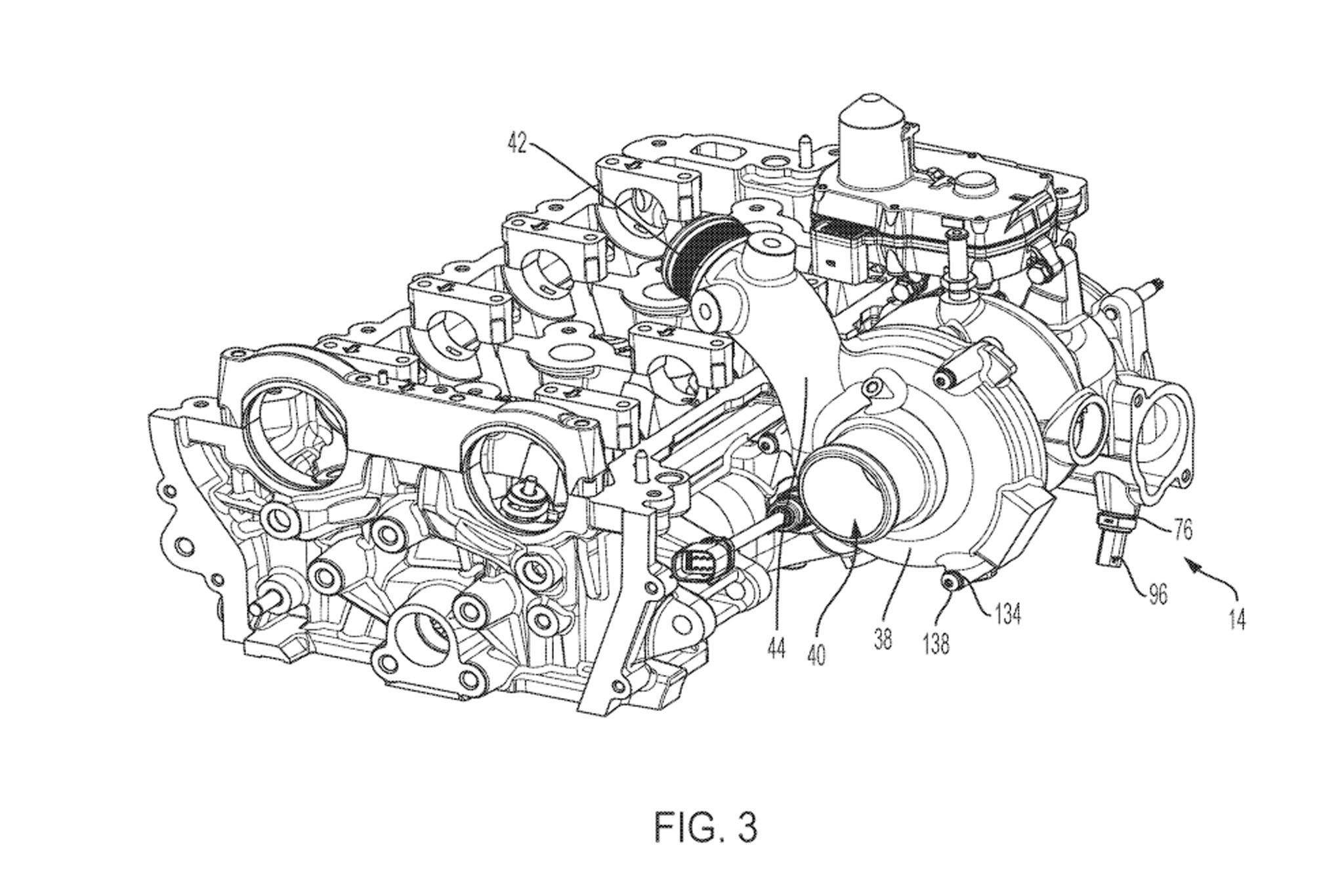

The patent was only just published on March 9, but it was formally submitted to the U.S. Patent and Trademark Office back in May of 2020. As hinted at above, the purpose of this sort of system is to reduce the number of parts in turbocharged engines and reduce cost. In order to achieve these savings, a lot of the turbo system is cast directly into the head.

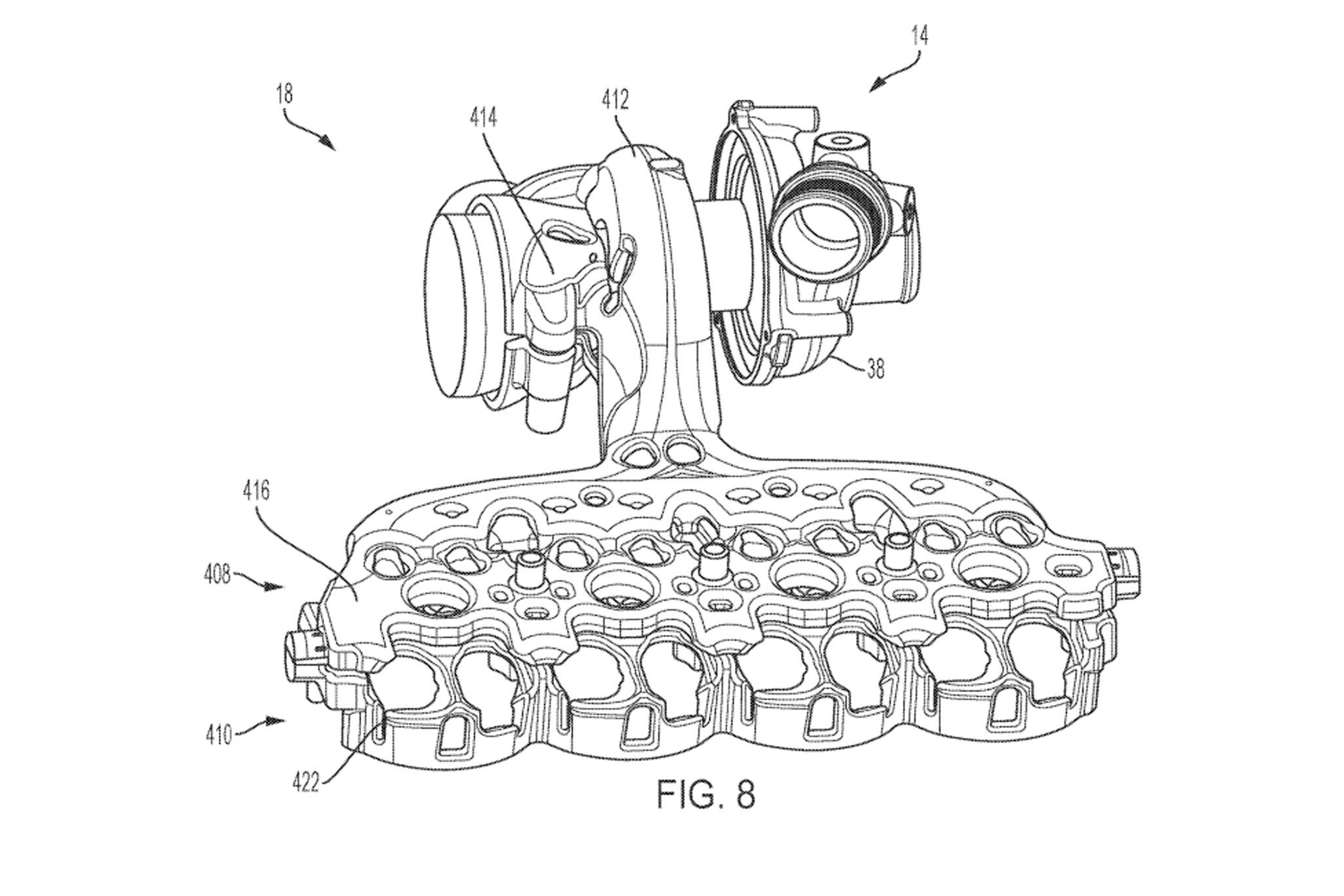

The exhaust manifold is, of course, cast in, as is the exhaust housing. It goes a lot further than that, though. The document notes that parts like the wastegate, or at least a place to mount the moving parts of a wastegate, can be cast directly into place, as can parts of the compressor side of the turbo. The core of the turbocharger—the bearings, shaft, turbine, and compressor wheel themselves—are part of a separate cartridge.

This patent is very detailed, not only in its description but also in its illustration. I’m not just saying this to make note of the fact that it has good pictures, I’m saying that what we’re seeing in the illustrations may be indicative of production intent. Specifically, the fact that this system is mated to a four-cylinder engine in such detail probably means that’s where we would see it in real life. It could be applied to other layouts, yes, but I see the level of detail here indicating that this isn’t just a general placeholder patent intended to protect a concept.

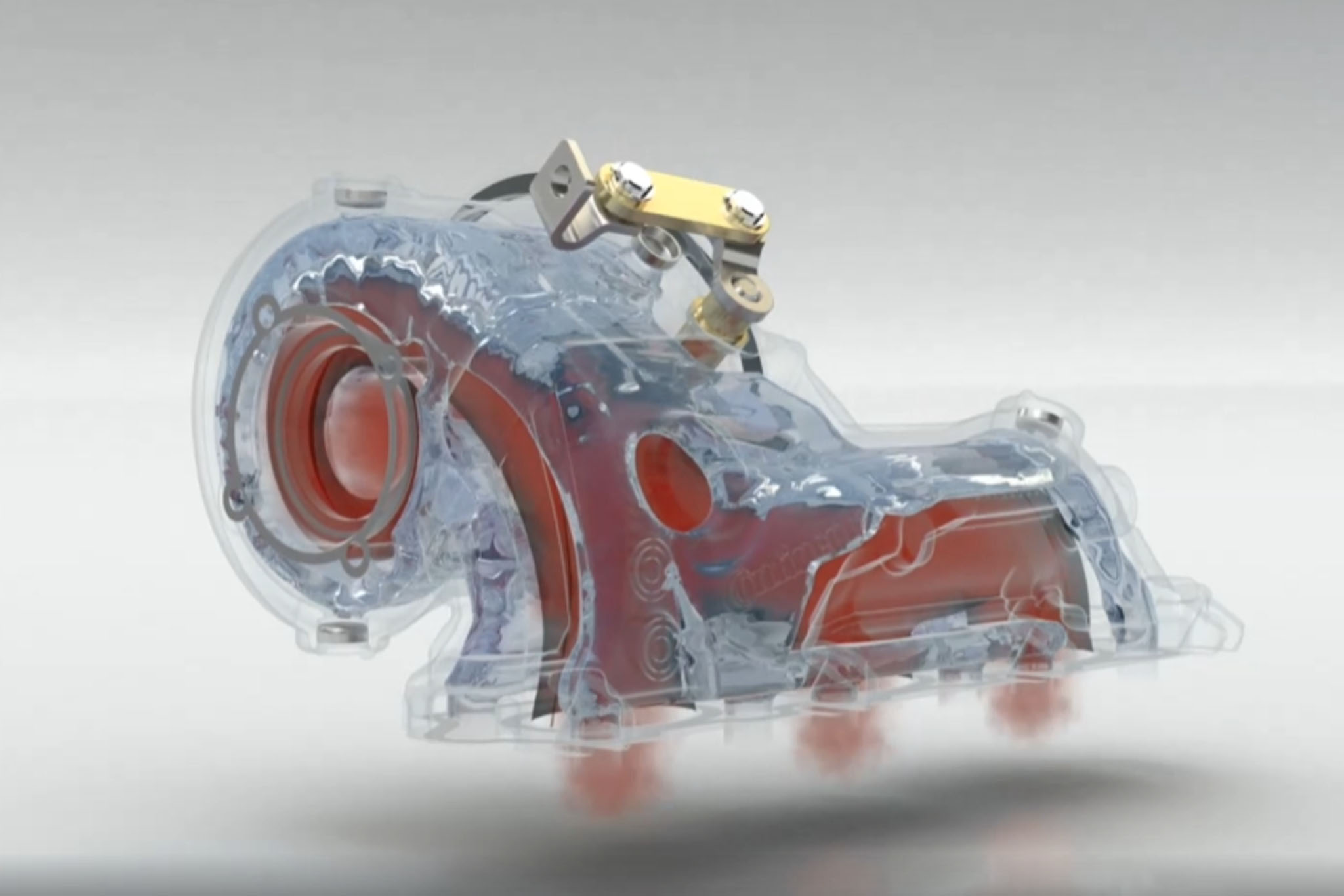

But if you’re anything like me, there’s one big question in your head now, and that’s how to manage the heat. For this, the automaker’s engineers got creative. The following solution is either a clever and workable concept or a very, very bad idea. I’m honestly not sure yet. In a nutshell, the entire head is aluminum, including the exhaust side of the turbo. Water jackets around the exhaust housing will cool it to ensure it doesn’t fatigue or melt. Most turbo housings are made from steel or iron for this exact reason. Aluminum compressor sides for turbochargers are the norm, and indeed this system presumably has an aluminum compressor end, but that’s because the “cold” side of the turbo isn’t subject to such extreme temperatures.

The document notes that this water jacket for the turbo also cools the aluminum wastegate, and it may be plumbed right into the head. Alternatively, the coolant can be routed to and from somewhere else on the motor, perhaps in an attempt to keep the head cool and prevent detonation. It’s worth noting that a portion of the charge air ducting to an intercooler may also be cast into the head.

This idea has seen a little development elsewhere. BMW’s turbocharged three-cylinder engine, the B38, has an aluminum exhaust manifold with an integrated turbo housing. It’s also similarly water-cooled like this design from Stellantis. However, that system is not cast directly into the head as this one is. If something goes wrong and a recall is forced, BMW just has to replace the housings. If the same happens with Stellantis’ design, it could be a huge problem.

It also must be said that this is bad for serviceability and aftermarket tuning. If a conventional car today has a failure in its turbo system, those parts can just be replaced. With this setup, that’s no longer an option. An entire head has to come off or some serious jerry-rigging must be done to correct a potential failure. The bottom line is that this setup heavily focused on increasing manufacturing efficiency, with other considerations far more compromised.

Indeed, the patent document explicitly states that all of this is being done to reduce “cost and complexity.” Turbo systems today work great and they’re pretty reliable, as the text notes; however, the metals required to make the exhaust ends of turbos—it specifically mentions nickel and chrome—are expensive, as is the slew of componentry needed to assemble the systems. “Gaskets, fasteners, mating tubes, ducts and other components” all translate into an expensive and complex piece of hardware. That’s not such a big deal for an enthusiast looking to add some power later in a vehicle’s life, but it is a big deal for an automaker producing millions of vehicles.

The bottom line is that Chrysler engineers, if you can still call them that, are wading into an unknown ocean of innovation here. Combination turbo housings and exhaust manifolds have been done before, as have exhaust manifolds integrated into heads. However, at least in terms of a mass-market automotive product, integrated turbos have not. Just the same, a turbocharger exhaust side made of aluminum, which this design hangs its hat on, has not been widely developed.

If it gets it right, Stellantis could save a lot of money and make its vehicles simpler. If it gets it wrong, it’s a potential warranty and recall nightmare. In any case, it’s interesting engineering, and we’ll have to wait and see whether it ends up on any vehicles in the Stellantis family. Will Ram follow Chevy’s lead and put a big four-cylinder turbo engine in its full-sized pickups? Will Dodge make every Mopar enthusiast on the planet angry and make a four-cylinder Challenger? Drivetrains for either of those cars could feature this sort of turbo system.

Got a tip or question for the author? You can reach them here: peter@thedrive.com