To celebrate National Nanotechnology Day, Ford announced Tuesday that it will become the first automaker to use graphene parts in its vehicles, starting with the Mustang and F-150 by the end of 2018.

Graphene is a material made from a hexagonal structure of carbon atoms, first isolated in 2004. Its uses are almost endless, as it’s about 200 times stronger than steel, but lightweight and flexible. Graphene makes an excellent electrical conductor and also a superb insulator of sound. Its exceptional properties made it one of the hottest topics of science magazines of the era, which presented it as a panacea to all problems engineering, and ignored some of graphene’s biggest flaws.

While graphene is already used in sporting equipment like tennis rackets, and in some electronics, it’s tricky to manufacture, and its production can also generate a byproduct called graphene oxide, which can be explosive when dispersed in air. Most commercially-available graphene is in small flakes, not the large sheets that would be necessary to manufacture larger items, such as a car’s chassis.

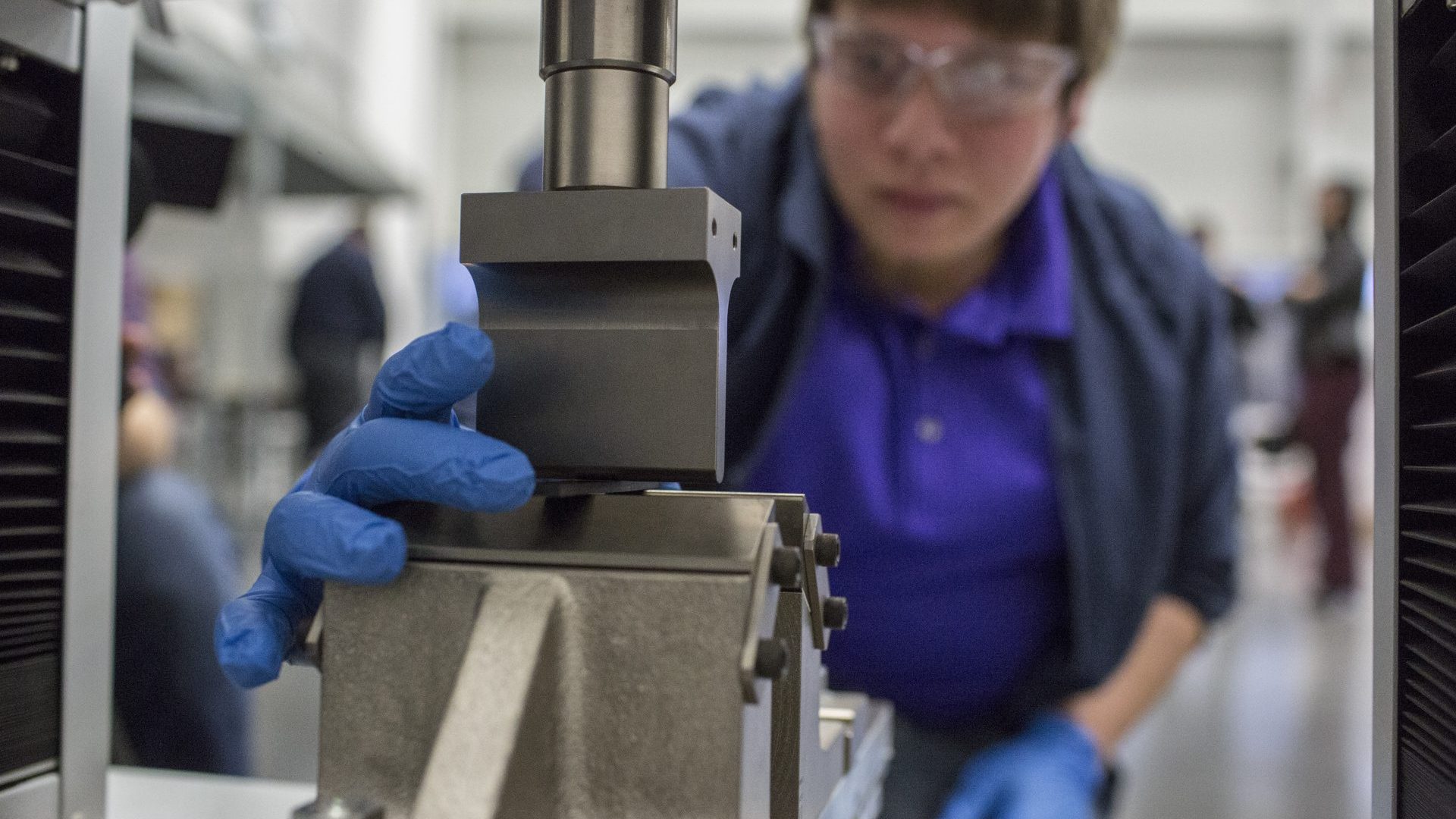

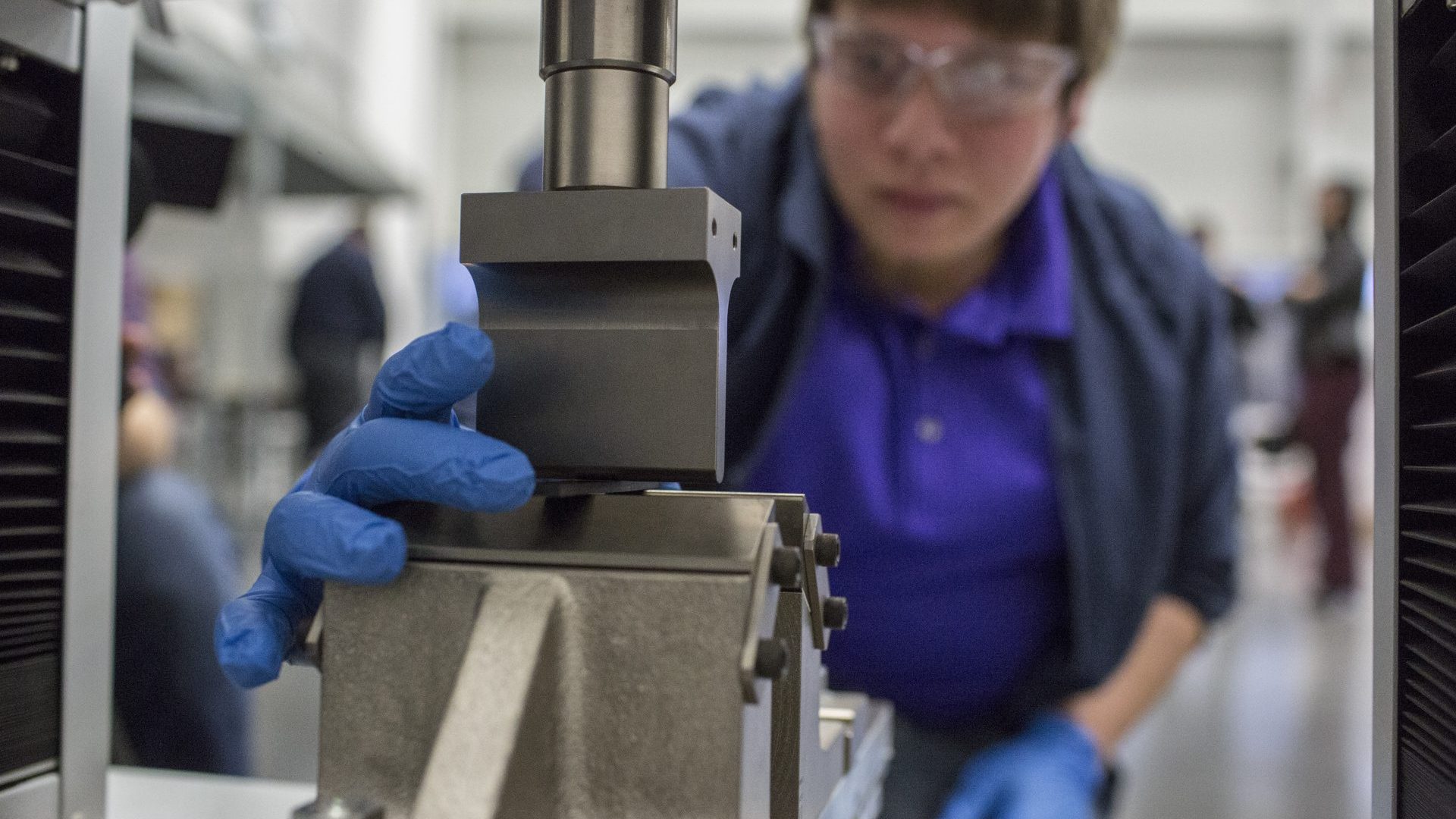

Ford acknowledges the difficulties of graphene manufacturing and use, but in partnership with Eagle Industries and XG Sciences, it has determined a way to make use of graphene reinforcement in certain components to strengthen and lighten them, as well as reduce noise. Since 2014, Ford and its partners have trialled graphene-reinforced foam covers for noisy components such as the fuel rail, pumps, and belt-driven pulleys or chain-driven gears on the front of engines. The resulting parts are 17 percent quieter, 20 percent stronger, and 30 percent more heat-resistant.

“The breakthrough here is not in the material, but in how we are using it,” stated Debbie Mielewski, Ford senior technical leader for sustainability and emerging materials, in the company’s release. “We are able to use a very small amount, less than a half percent, to help us achieve significant enhancements in durability, sound resistance and weight reduction—applications that others have not focused on.”

“We are excited about the performance benefits our products are able to provide to Ford and Eagle Industries,” added XG Sciences CEO Philip Rose. “Working with early adopters such as Ford Motor Company demonstrates the potential for graphene in multiple applications, and we look forward to extending our collaboration into other materials, and enabling further performance improvements.”

Graphene may not yet be ready to replace carbon fiber as the preferred chassis material in high-performance vehicles, but this is a crucial step on the path toward a lightweight future.