Having discontinued its now six-decades-old (sort of) 6.75-liter V8 engine in the Mulsanne, Bentley is all set to revive another part of its history with a hyper-limited production run of 12 Continuation Blowers built to the specifications of Sir Tim Birkin’s famed 1929 4½-liter “Team Blower” endurance racer. Though such recreations are getting more popular these days, these will be the first pre-war continuation cars built by a major manufacturer—and Bentley is ready to start screwing together the first prototype.

Getting to this point hasn’t been easy. The team at Crewe had to disassemble the #2 team car still owned by the factory to laser scan its frame and other components, then commissioned skilled experts all over the UK to craft the new parts based on a combination of the fully digital CAD data and the original 1920s engineering drawings and drafts.

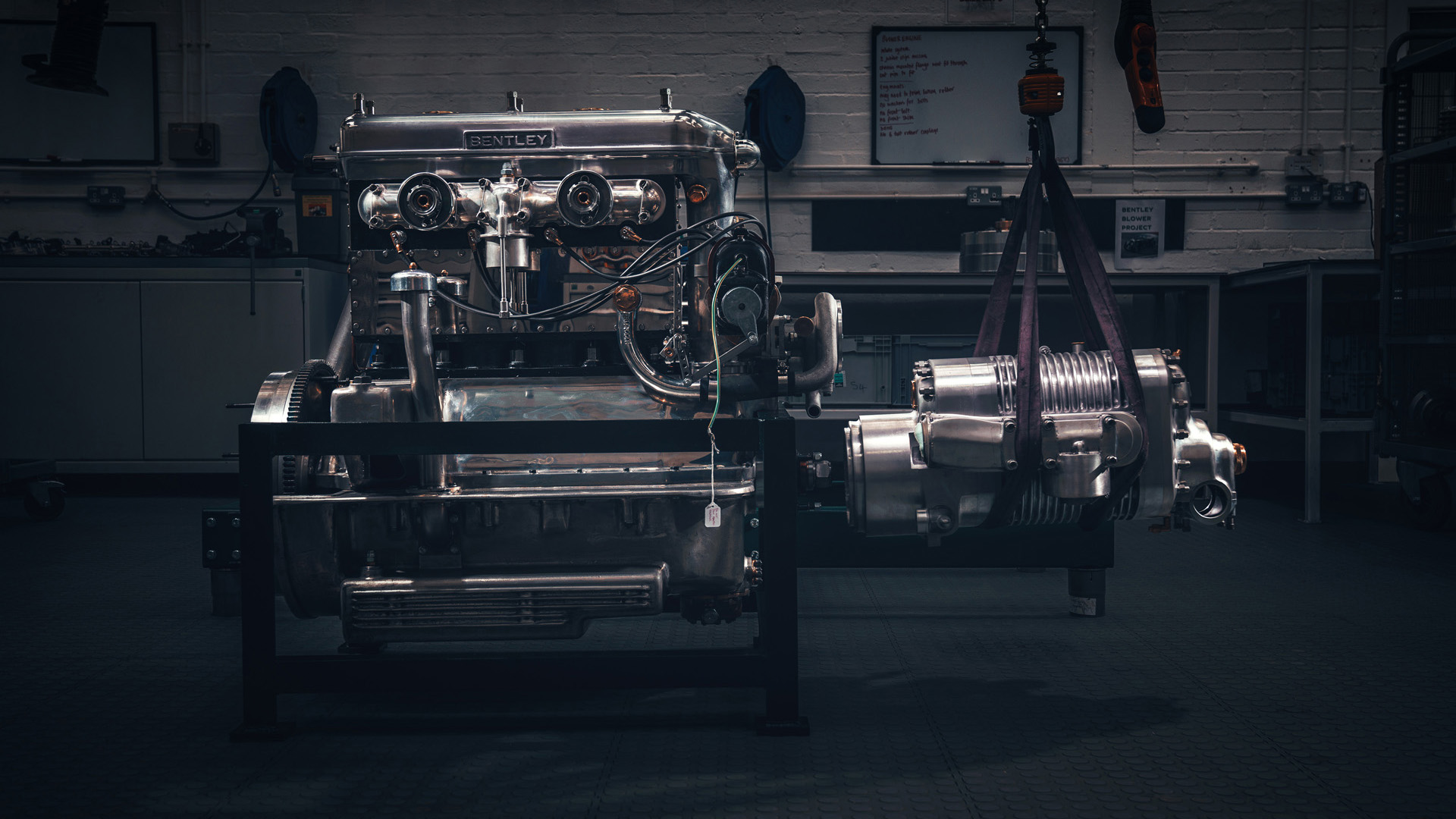

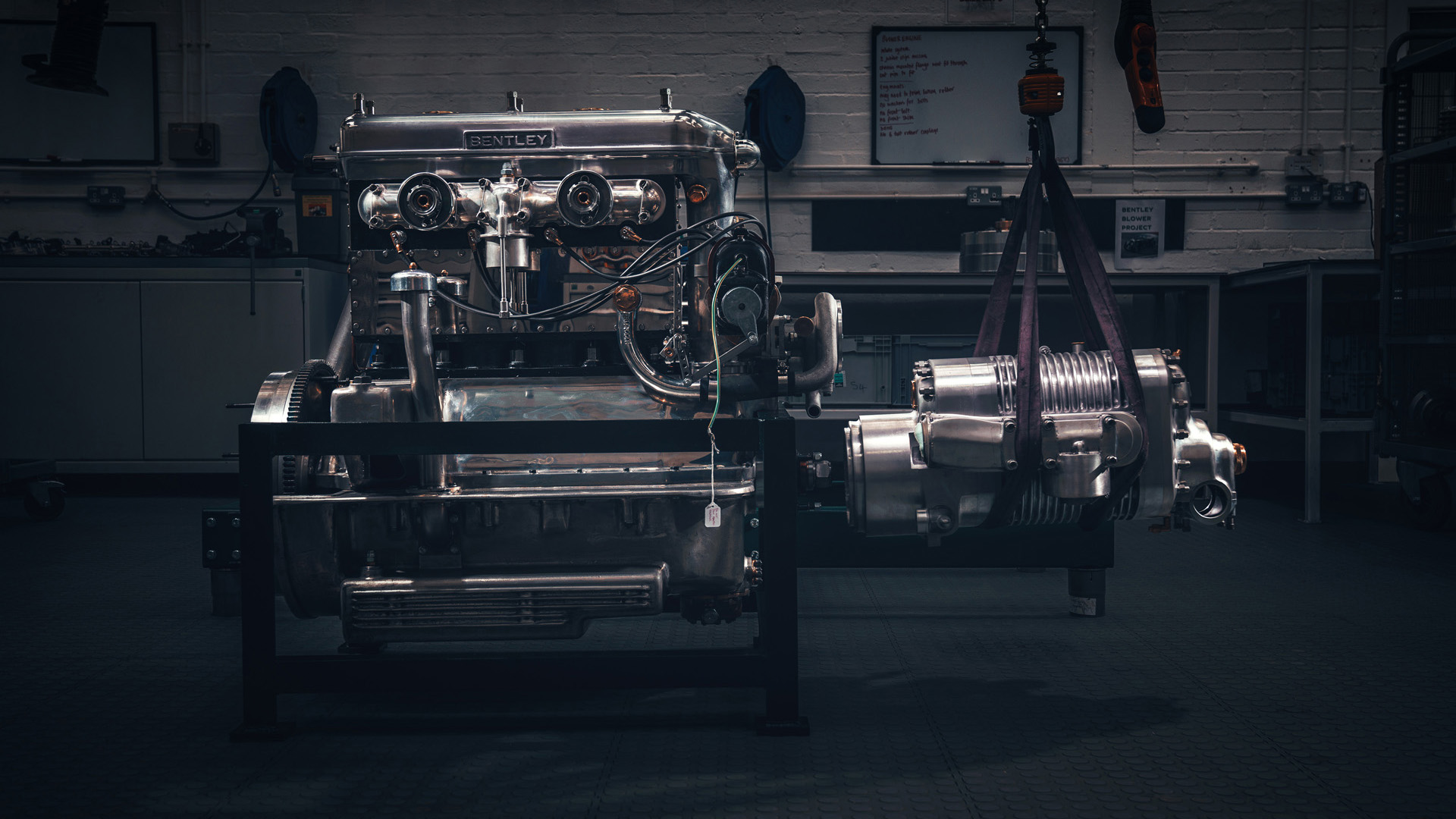

Bentley’s “Car Zero” engineering prototype is powered by the same W.O. Bentley 4½-liter four-cylinder design as the first blown Bentleys in 1929, complete with a remade Amherst Villiers supercharger.

The new Blowers’ chassis is made in heavy-gauge steel, which is hand-formed and riveted by the specialists at Israel Newton & Sons Ltd. This 200-year old company traditionally makes boilers for steam locomotives and traction engines, which means Jay Leno probably has their number somewhere. Bolted to that massive frame the leaf springs and shackles sourced from Jones Springs Ltd, a specialist with nearly 75 years of experience in the blacksmith business.

The Continuation cars use The Vintage Car Radiator Company’s mirror-polished, nickel-plated radiator shells and hand-beaten fuel tanks, all formed in steel and copper. The engine itself was recreated by Bentley Mulliner with the expert support of specialists including NDR Ltd. It still features the pioneering airplane-inspired solutions of W.O. Bentley, who chose to go with aluminium pistons, an overhead camshaft, four valves per cylinder and twin spark ignition for his race-ready luxury cars. Thanks to the roots-type supercharger, this huge four-cylinder engine is expected to produce at least 240 horsepower, along with plenty of torque.

Last but not least, those all-important Blower headlamps were recreated by Vintage Headlamp Restoration International Ltd in Sheffield. This is a father and son team well known for their silversmithing skills.

As you would expect, the new ash frame created by Lomax Coachbuilders went straight to Bentley’s Mulliner Trim Shop, where the final stages of carpentry will involve plenty of hand-trimming.

Now, the next thing Bentley’s test pilots can look forward to is managing the heat levels of the Blower prototype’s enormous 15.7-inch drum brakes. Pre-war fun engineered for twelve lucky people living almost a century after Sir Tim Birkin’s glory days.

Got a tip? Send us a note: tips@thedrive.com