Saving weight is a key part of performance and efficiency for any vehicle, and competitors in racing series like Formula 1 go to great lengths to shave every gram off their car designs. Carbon fiber is all the rage, even making it into some structural parts of regular cars like the BMW i3, but one technology really coming into its own recently is 3D-printing using lightweight metal alloys.

Update: Friday, January 22 @ 4:30pm ET: A previous version of this story reported that a pedal like this could cost upwards of $150,000 to produce. After publication, EOS reached out to say that the original source for that number was mistaken and clarified the price estimate. The relevant passage has been updated.

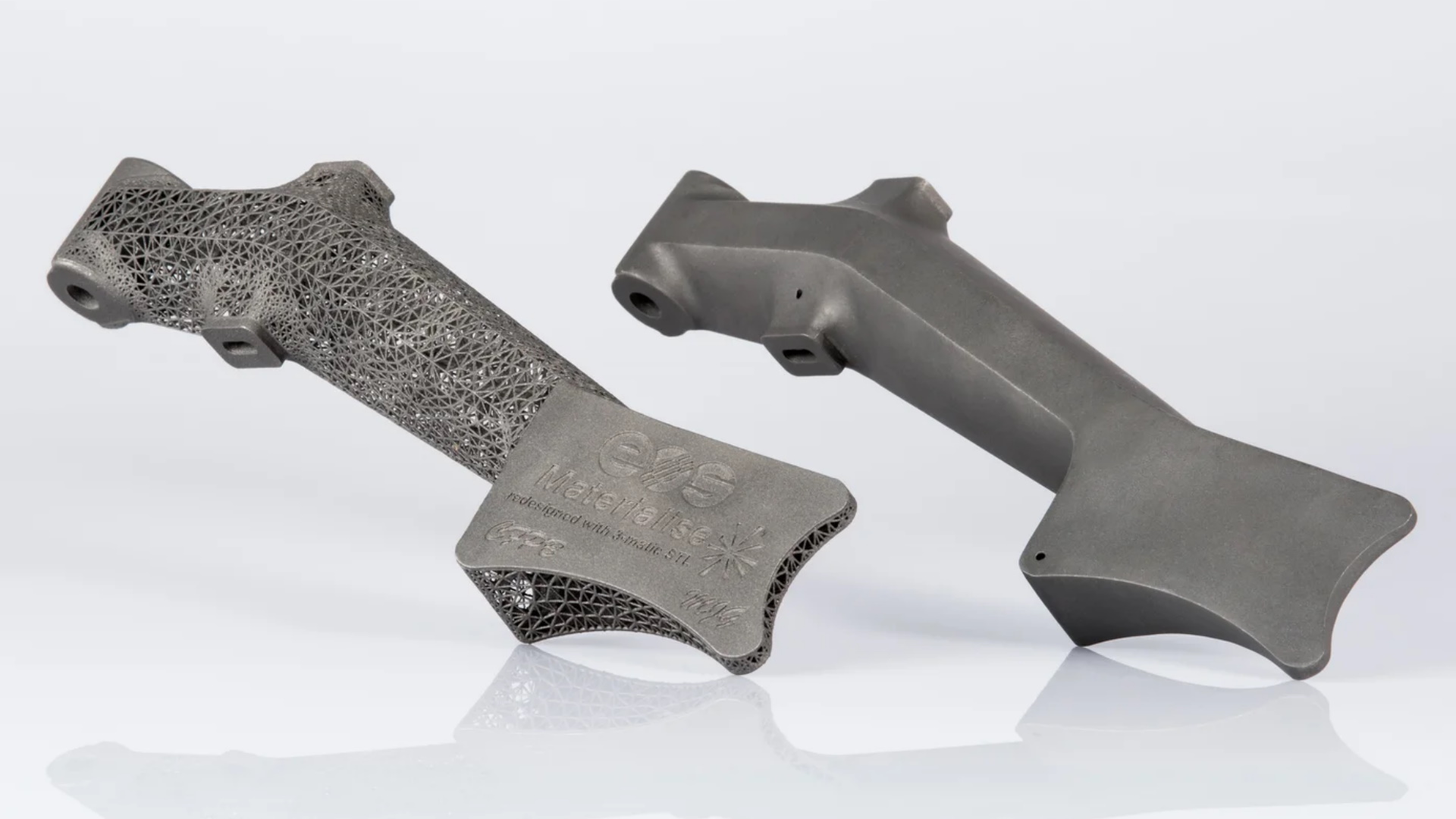

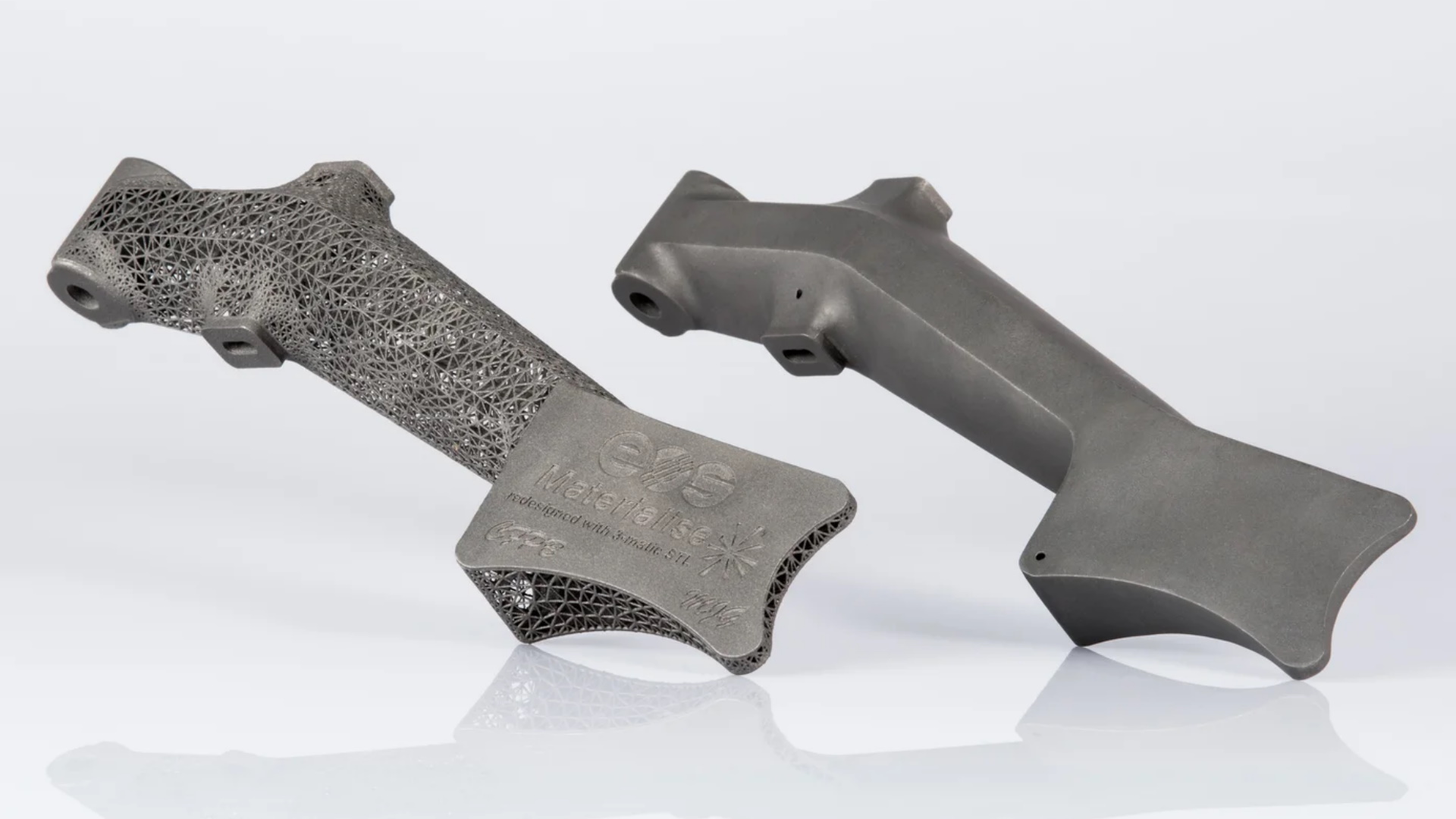

EOS, a manufacturer of “Selective Laser Sintering” 3D-printers, is one of the companies spearheading this effort. As a tech demo, a customer of the company’s machines challenged its employees to utilize the latest in topology optimization and SLS printing technology to not only lighten a racing brake pedal but make it stiffer as well. The result of all of this work is one of the strangest-looking automotive components we’ve ever seen, a computer-optimized web of titanium that weighs just 178 grams, or roughly 6.2 ounces.

SLS, for those who don’t know, is not like the typical nozzle-extruding 3D-printing. Instead of spitting out a solid stream of liquid material that later solidifies, SLS machines lay down a thin layer of powdered metal that is then melted by a very powerful computerized laser. After the part is pulled out of the pile of metal powder—plastic powders can also be used, and nylon is a popular one—it’s typically baked in an oven to further increase its structural rigidity. This method is popular with complex parts like the brake pedal above, as support material for the prints is less of a concern when compared to a typical extruder-style machine.

EOS says SLS allows it to quickly work on different designs of parts such as this brake pedal, and with greater optimization, the company claims an even lighter pedal would be possible. It says a further reduction of 80 grams could be had, meaning an even more skeletonized component might weigh as little as 98 grams, or about the same weight as four AA batteries. In racing series as competitive as Formula 1, these gains are definitely worth it; however, they do come at a cost.

A previous article cited the cost for a pair of these things at $150,000, but that’s simply not the truth. These pedals are a demo, not something you can really buy, and they’re therefore not specced for racing use. EOS estimates that, minus the design and engineering overhead that it would take to create such a part, a single unit would cost around $450, nowhere close to the incorrect six-figure number. An EOS representative says the company has no idea where that number came from.

Now, seeing as how cheap these things actually are, somebody just needs to make some 3D-printed titanium parts for my Cobalt. Now that will be sweet. What’s the point of this titanium 3D printing if there are no Cobalt SS parts in it for me?

Got a tip? Send us a note: tips@thedrive.com