Featherweight carbon fiber wheels may have stamps of approval from Ford, GM, and Porsche, but large swaths of the automotive world remain unconvinced they have much of a future. Enthusiasts across the expertise spectrum from Facebook commenters to Gordon Murray believe their weight savings don’t justify their extreme cost, and that they’re too fragile to use in the real world.

Ash Denmead, the Engineering and Design Director for Carbon Revolution, couldn’t disagree any more strongly. Not only does he see carbon fiber wheels as a serious challenger to traditional alloy wheels, he thinks they boost efficiency enough to make them essential for everything from electric vehicles to commercial trucks. And while many technologies promise to change the auto industry at some undefined later date, he believes the dawn of the carbon age might be only a few years out, Denmead shared during a recent chat with us.

Denmead’s carbon thread is tethered to Deakin University, where Carbon Revolution’s factory is located today, and where Denmead spearheaded engineering for his school’s Formula SAE team. In those days, he and his classmates used homemade fiberglass molds to lay up tiny 13-inch wheels to boost the performance of their scratch-built race car. Before long, their manufacturing capabilities grew, allowing them to produce small batches of prototype wheels, some of which they used on their own personal vehicles. “When I look back, it was pretty sketchy,” Denmead remarked.

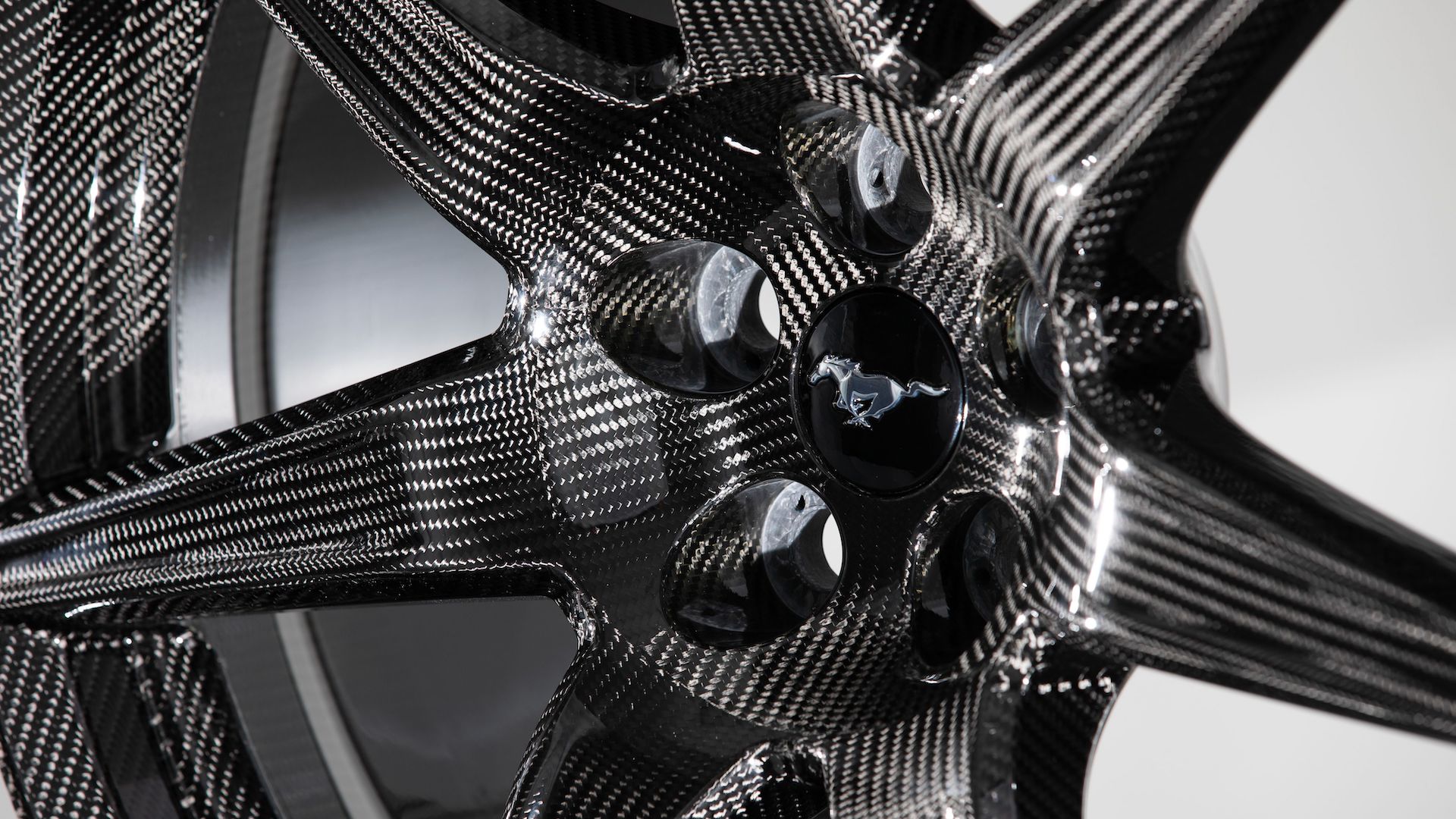

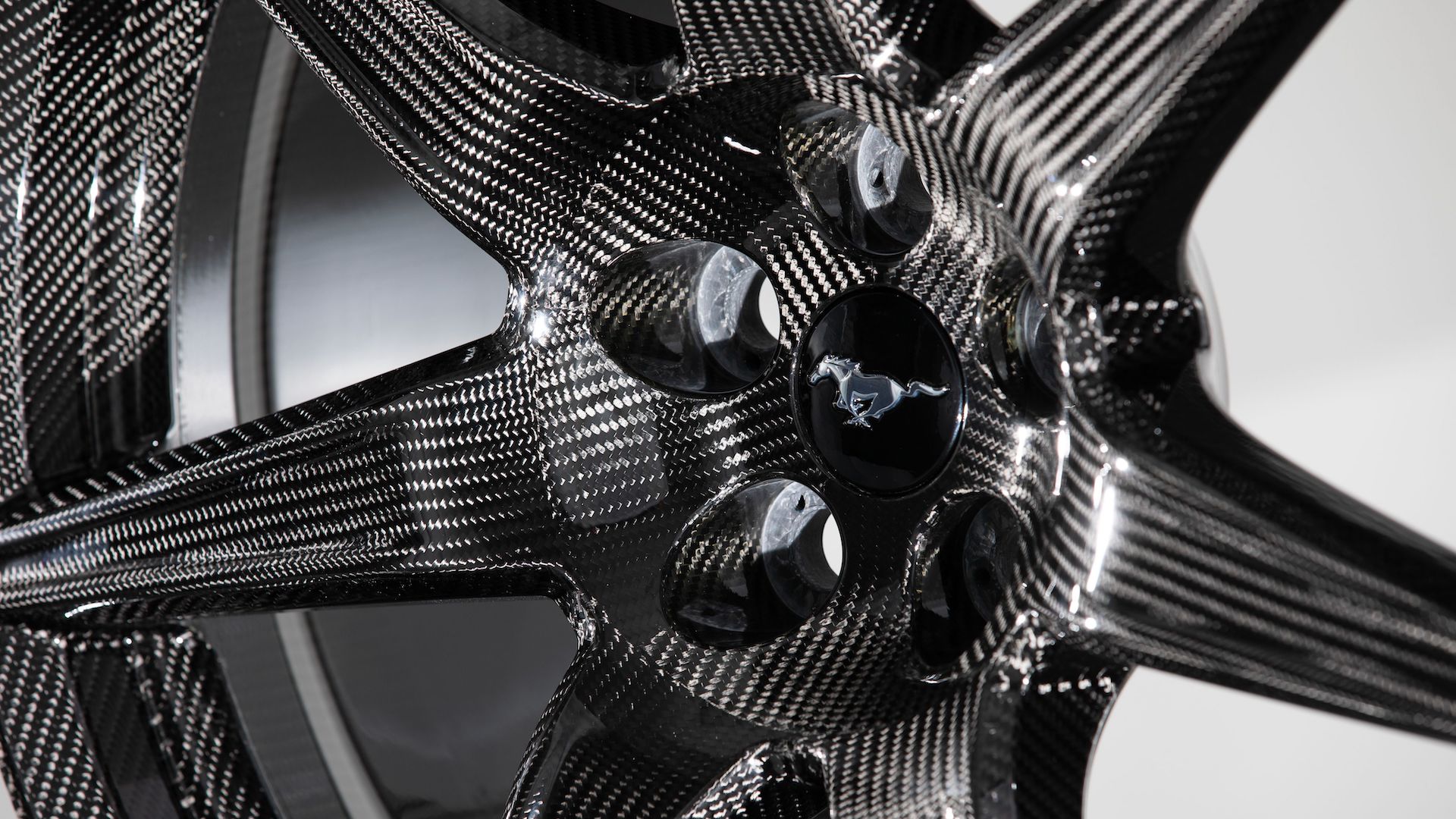

Since then, Carbon Revolution has grown exponentially, and today supplies the lightweight wheels used on tens of thousands of cars rolling around North America—from Ferraris and Porsches to the Ford Mustang Shelby GT500 and 2023 Chevy Corvette Z06. High-performance cars, though, are a limited market by which the benefits of weight savings are already accepted. Denmead is much keener about carbon wheels’ potential for more pedestrian markets, like electric vehicles.

“You get a multiplier effect by reducing mass in a wheel compared to reducing mass in other parts of the car,” Denmead explained. “Less energy to speed the wheel up, less energy to then slow it down under braking.”

Less energy use immediately translates to enhanced range, and in turn, effectively hastens recharging too. And because of its material properties, carbon fiber’s weight advantage only increases with wheels designed to optimize aerodynamics.

“You can make a really aerodynamic wheel out of metal, but when you do that, typically with metal, the wheel gets really heavy,” Denmead explained. That becomes especially pronounced on large-diameter wheels, like the 24-inchers that’ll ship on the Chevy Silverado EV. On aerodynamic wheels of that size, carbon fiber can cut weight by up to 45 percent, depending on how much extra durability the customer wants.

“With carbon fiber, we can do really cool things and have very thin wall structures with hollow sections and achieve that aerodynamic style, or performance without the weight penalty,” he continued. “We’ve got customers out there interested in 24- and 26-inch wheels as standard fitment on cars.”

Speaking to their durability, Denmead knows cracking carbon fiber wheels is still a common fear, but it’s a problem he says doesn’t worry him in the slightest. “You can’t be frustrated by it,” the engineer said. “The CEO here, Jake Dingle, ran [our wheels on] a BMW 320d, and he lives in Melbourne. Every day he would drive 200 kilometers to the factory and back… [and] he must have done that for five years.”

“There’s like 40,000 wheels out there in North America on the road, so we’re very much at the point where the technology’s proven,” Denmead emphasized.

It’s not just Carbon Revolution’s own standards its wheels have to meet, either. They must pass automakers’ sniff tests, for it’s they who stand to lose customers over any problems that may arise. If car companies—some of the most risk-averse businesses on the planet—didn’t think carbon wheels were ready for primetime, Carbon Revolution wouldn’t be where it is today.

But the journey here has been a long one, in part due to the lengthy process of design and testing each wheel undergoes. Carbon Revolution takes a proposed design and simulates its performance against fatigue and impacts, taking into account everything down to the type of resin used to the direction of carbon weave in each layer. “Our customers are very demanding on the durability testing, so to design a wheel and get it into production is usually two to three-year process,” Denmead explained. “So [a] very extensive design phase, internal simulation of the performance of the wheel.”

After achieving sim approval, a slew of real-world testing follows on prototype wheels to ensure they are more than up to the task. “We have to pass all of those tests before those wheels or that wheel design can get fitted onto a vehicle and put on the road.” Then, Denmead says, the automaker performs its own testing on prototype vehicles—these wheels live an unseen life of testing, abuse, and more testing before they ever get around to rolling into a customer’s driveway.

It’s this performance-proven, OEM-backed tech that Denmead and his colleagues think could make EVs leaner, and thus greener. Between carbon wheels’ weight savings and aerodynamic designs, Denmead says efficiency gains of around five percent are possible. On an EV with 300 miles of range, that’s an extra 15 miles of range gained by just swapping the wheels out. That could be the difference between making it home or not, or reaching a nearby charger. What’s more, it’d also save customers money, and Denmead is optimistic about the direction prices are going.

Back when the company first started selling its wheels in the aftermarket, one of its early customers was Jay Leno, who in a recent video on his YouTube channel said the wheels used to cost $20,000 apiece. “We were never charging $80,000 for a set of wheels. That’s just never, that was never the case. But it is true that the cost has reduced significantly over the last 10 years,” Denmead told us.

While the wheels were expensive—just not that expensive—Denmead agrees that they are coming down in price, adding that affordable aftermarket carbon wheels—say, $500 a corner—are still on a sharp decline, and may be feasible by the mid-2020s. “You might be out to five years away, four or five years away,” he said, citing a need to increase volume production.

By then, Denmead expects any trepidation towards servicing vehicles with carbon fiber wheels will have evaporated as well. Owners of vehicles equipped with the currently exotic-looking wheels have often expressed frustration at getting somebody to actually change a tire on them, or rotate them. “It’s just a general immaturity of people’s understanding,” the engineer explained. “There’s no difference in changing a carbon fiber wheel to an aluminum wheel, you use the same equipment, there’s videos out there on how to do it. It’s just, unfortunately, people are a little bit scared of damaging an expensive wheel, that’s all it is at the moment.” So as the prices go down, he thinks so will tire techs’ unease around carbon wheels.

The applications of this energy-saving tech are poised to affect a multitude of industries, from personal transportation to shipping and fleets, reducing energy consumption and making a small, but crucial dent in the global energy consumption of transportation. In the end, Denmead says, technology will march relentlessly on just like it has in the past.

“It’s the same thing that happened years ago with the trucking industry moving from steel wheels to aluminum wheels,” he concluded. The technology is undeniable, the savings are there, and in Carbon Revolution’s opinion, it’s only a matter of time before everybody clamors to have these lightweight wheels bolted up to their cars.

Got a tip or question for the authors? You can reach them here: peter@thedrive.com, james@thedrive.com