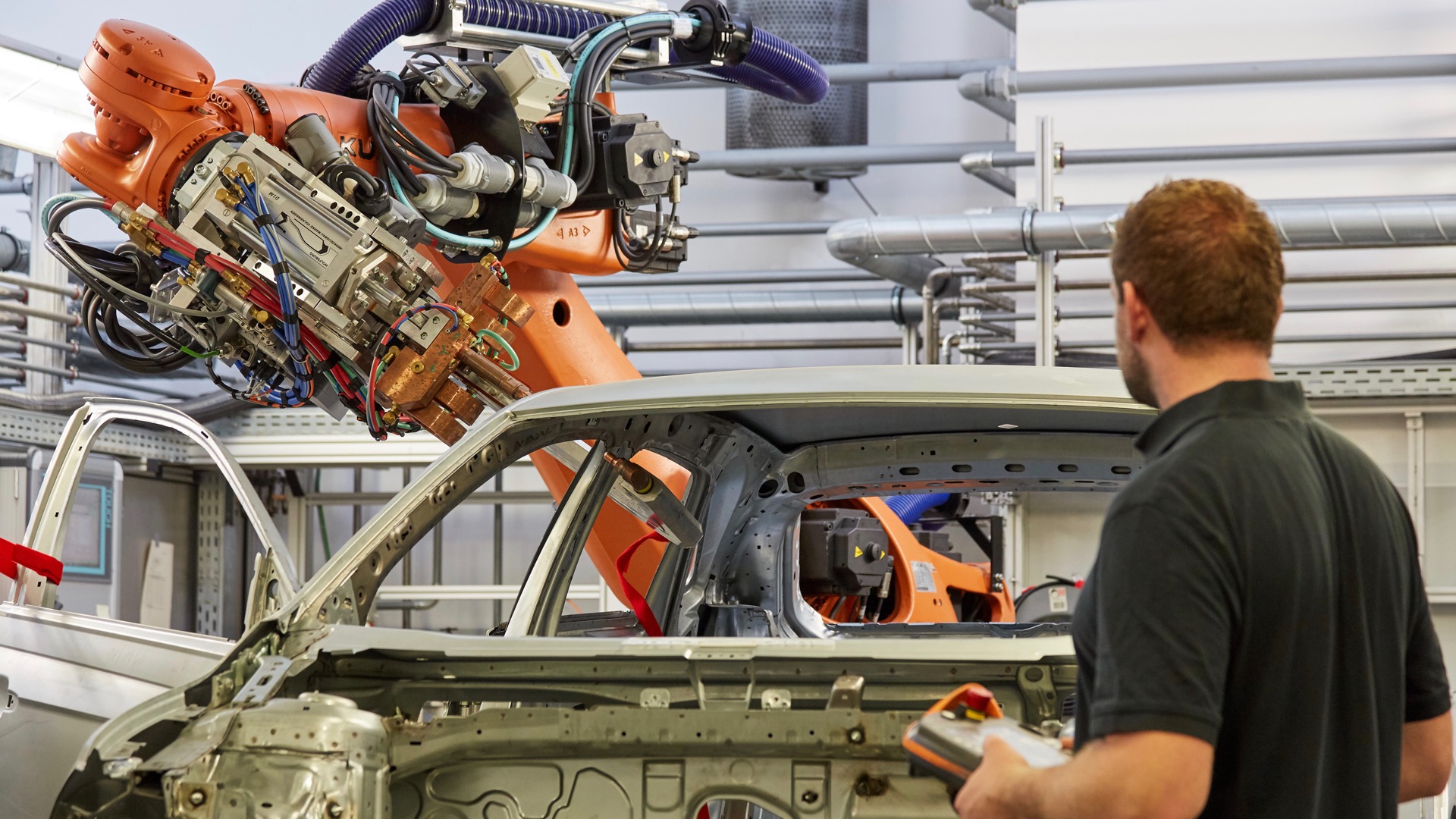

Several automakers have discussed 3D-printed car parts, but Volkswagen claims to be close to using them in mass-produced vehicles. That’s thanks to faster, simpler processes for printing metallic parts, according to a recent statement from the automaker.

The “HP Metal Jet” was jointly developed by the printing company, VW and supplier GKN Powder Metallurgy. The three brands unveiled the new printing process at the International Manufacturing Technology Show in Chicago. Volkswagen said it hopes to begin printing “structural components” for production cars within two to three years.

Like other forms of 3D printing, HP Metal Jet is an “additive” process, in which material is added layer-by-layer to form a part. In this case, the material is a metallic powder held together with a binder. In other forms of 3D printing, the material is then melted with a laser; however, the new process developed by VW and its partners “bakes” the material into a completed part.

3D printing is already suitable for one-off parts or prototypes (the record-breaking I.D. R Pikes Peak racer used some 3D-printed parts), but Volkswagen believes this new process will allow for the production of parts on a large scale. This eliminates the need for tooling, which is both expensive and time-consuming to set up, VW noted. Despite the potential benefits, the automaker is keeping expectations realistically in check.

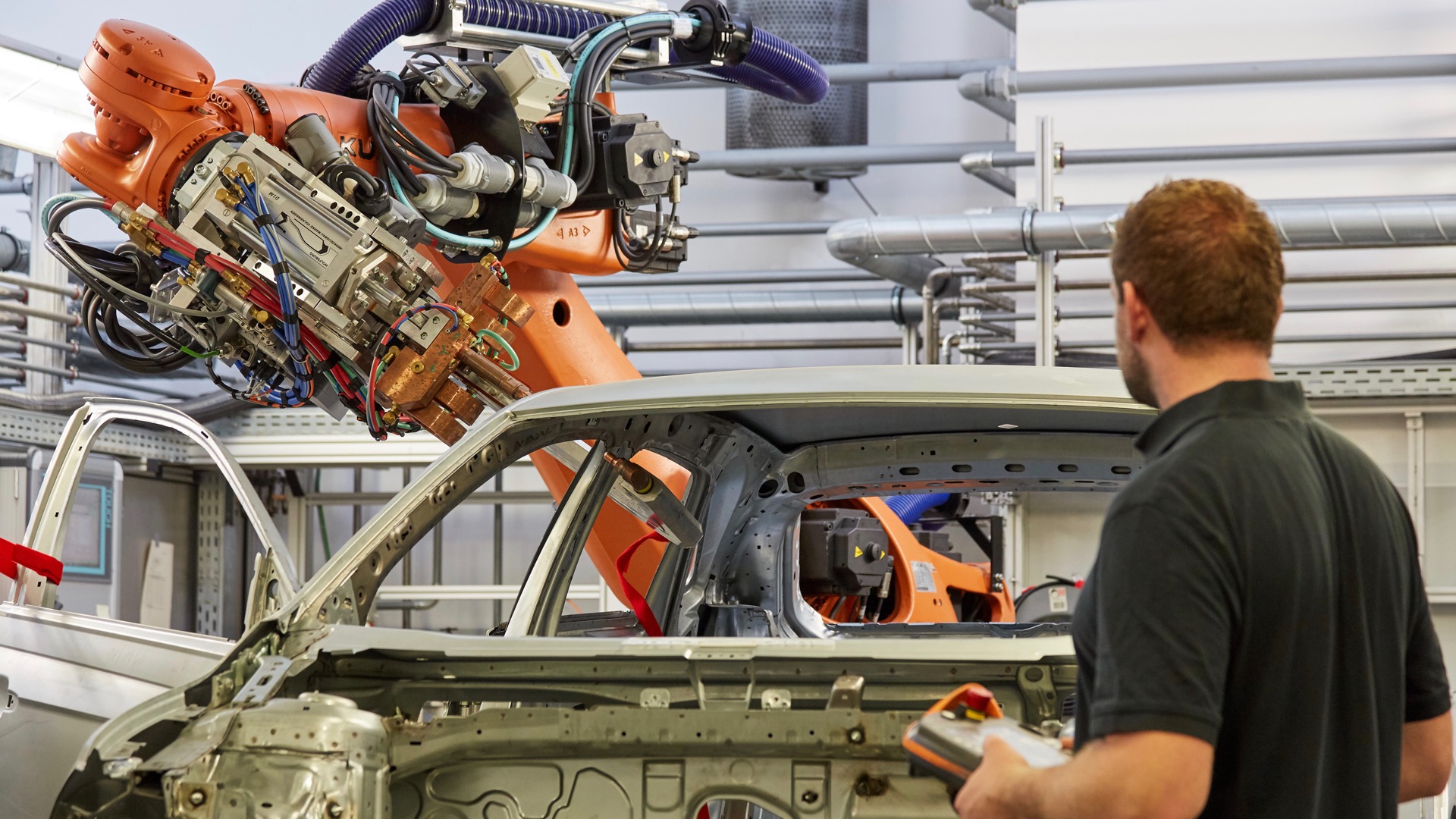

“A complete vehicle will probably not be manufactured by a 3D printer anytime soon, but the number and size of parts from the 3D printer will increase significantly,” Martin Goede, VW head of technology planning and development, said in a statement. “Our goal is to integrate printed structural parts into the next generation of vehicles as quickly as possible. In the long term, we expect a continuous increase in unit numbers, part sizes, and technical requirements—right up to soccer-size parts of over 100,000 units per year.”

Volkswagen is also looking at 3D printing as a way to personalize cars, something that’s also been discussed by Ford. Items like individualized tailgate lettering, gearshift knobs and personalized key fobs can already be produced relatively easily, the automaker explained. VW said it plans to offer these kinds of options to customers “as soon as possible.”