We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

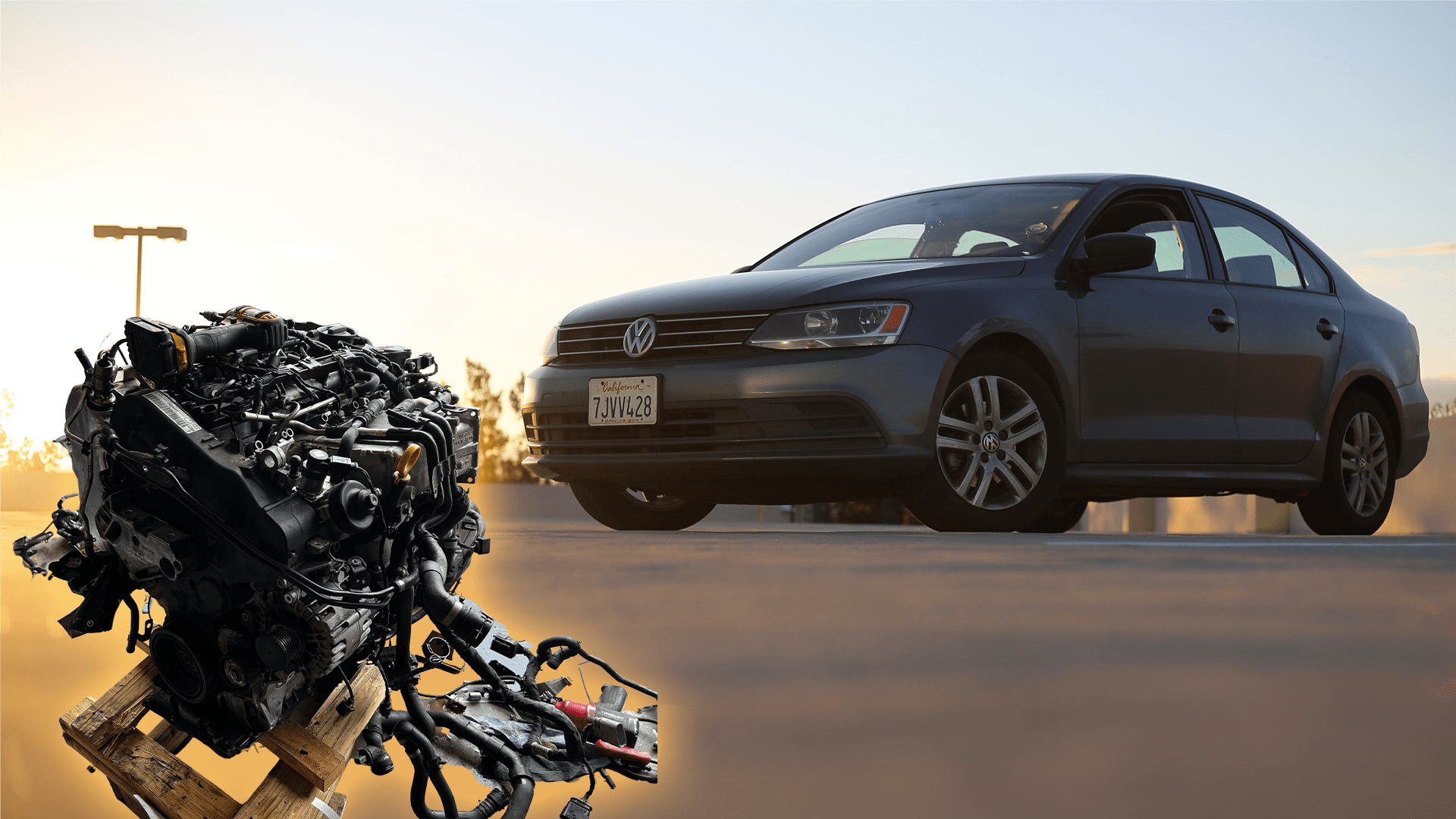

My true forever Volkswagen love is actually my 2015 Jetta TDI S, not my VW GTI, in weirdly nice gray and with zero optional extras. After 247,000 miles of faithful service and an unfortunate episode nearly leaving my mom stranded with a rattling engine, it sat beside my house with a blown motor. I should have bought a new car, but romance and stupid used car prices drove me to replace the engine in this modern technological marvel.

Technically, it is my mom’s car, but I chose it for her. My parents signed the paperwork for a Platinum Gray Metallic Jetta, and the beret-wearing Mr. Rogers caricature of a Volkswagen salesperson bid us adieu with a cute demonstration of the switchblade VW key. Such are the depths of my mom’s apathy toward cars that I got the real privilege of driving the Jetta off of the rainy dealer lot and homeward bound.

I loved it immediately. The 2.0-liter EA288 common-rail diesel engine has torque from 1,000 rpm and revs to 4,000 rpm, which is unusual for a diesel. Twin clutches snap shifts away, while a silent cabin and excellent ride quality make it an amazing highway car. It’s fun in the canyons with cheap economy car tires. Its exaggerated pitching and rolling motions during hard driving are befitting of the finest rental cars. Also, this car has genuine rarity. The EA288 was a one-year-only engine for the 2015 Jetta TDI, before The Obvious happened in September 2015.

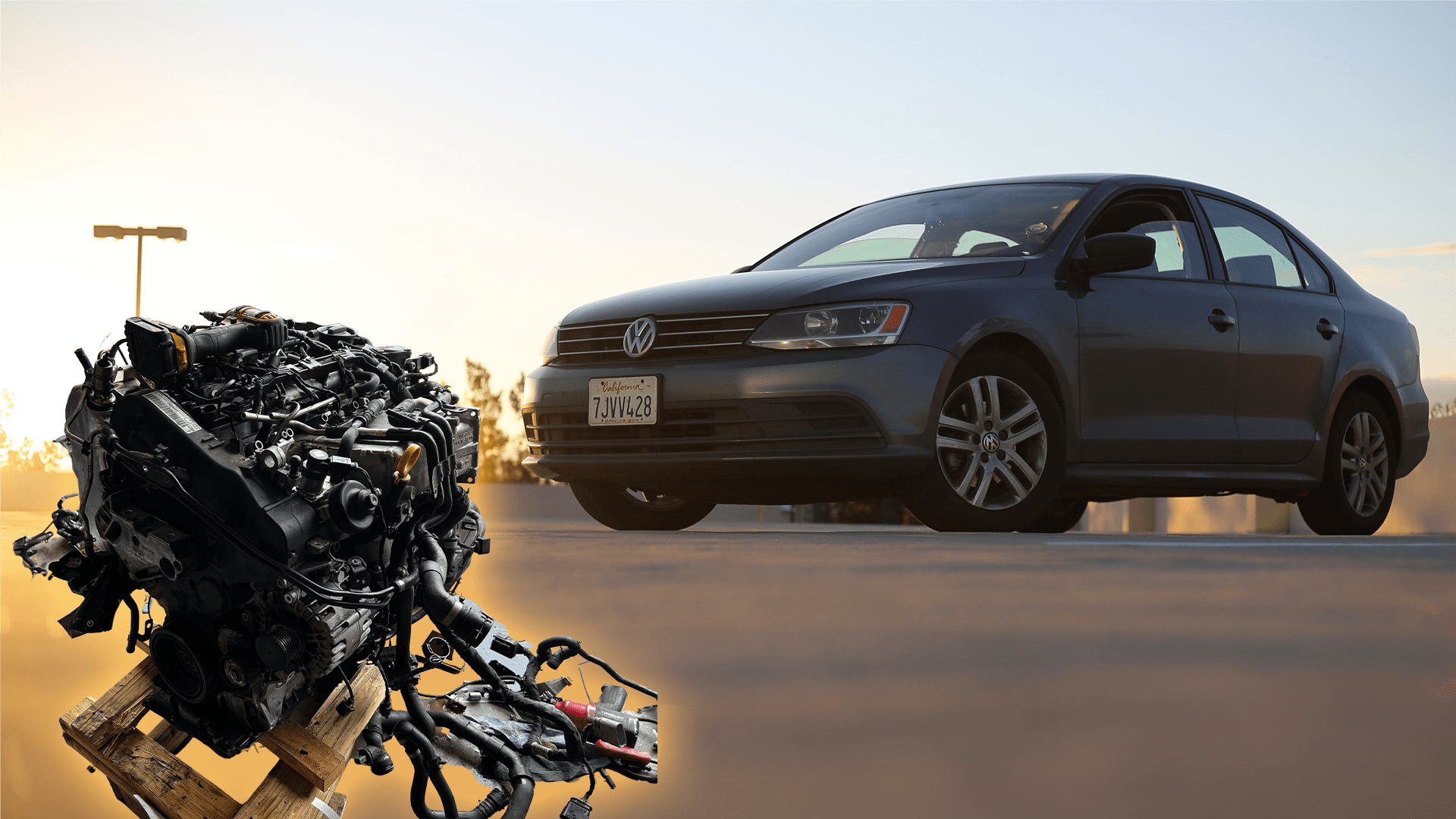

These qualities still exist even with almost a quarter of a million miles on it, nearly all of which have been trouble-free, even with the exceedingly complicated diesel engine. For the uninitiated: This engine has three combined liquid cooling circuits, three coolant pumps, a variable geometry turbocharger, a twin-stage oil pump for variable oil pressure, variable valve timing, urea injection, cooled exhaust gas recirculation, and a water-to-air intercooler. It represented the pinnacle of VW’s diesel tech until seven months after we purchased the car. That’s when Dieselgate happened.

Though I did know better than believing TDI “clean diesel” was truly cleaner than gasoline, it was still something of a shock when Dieselgate broke the news. We suddenly owned a car that was an active participant in automotive history. The buyback offer arrived months later, but my parents liked the car so much that they kept the car and took settlement money. We never looked back, thus we have the blown-engine Jetta TDI.

I replaced the engine in my driveway with my moderately advanced tools with no lift. Why? Well, I could fix this car for less money than the current marked-up new cars that would replace it, and this car is actually the ultimate reliable backup beater. It’s also sentimentally special to me. I’ve experienced a strange amount of my life behind the wheel of this car, including many dates, hanging out with groups of friends, contemplative late nights, and coming-of-age experiences. It’s a special shitbox to me.

About three months ago, my mom reported that the car rattled, had a severe lack of power, and died as soon as she limped into the driveway. I set about figuring out why the engine exploded. The rattle was the most concerning part, but I still inspected the fuel system first and found no issues. Sometimes, the high-pressure fuel pump can fail on earlier generation TDI engines, but the issues were solved for the EA288.

The elephant in the room was that the car has a 130,000-mile timing belt interval. The other elephant was that this car is actually on its second engine after a freak dealer mistake at 47,000 miles caused a connecting rod to go on strike. So the current engine has 200,000 miles, of which the past 60,000 have been over the timing belt interval. It’s as simple as my parents did not believe me when I told them the engine would explode if they didn’t replace the belt. They didn’t, and the engine expressed its displeasure in the worst way possible.

I removed the valve cover and promptly found the remains of the valvetrain. It was a gruesome scene—pieces of valve rockers, lifters, and roller bearings lay sickeningly within the cylinder head. It was a total goner. Clearly, the timing belt had failed. After some more disassembly, the timing belt tensioner had given up the ghost.

Used parts prices work in a simple supply-and-demand way. The most reliable parts are rarely bought, so they are cheap. Parts that tend to break cost more money. The EA288 engine happens to be reliable and very cheap, so my dad managed to find one with 76,000 miles for $1,000 shipped to our door. A brand new, fully-dressed cylinder head would have cost $1,200, and I would have still needed to remove the engine because of the complicated exhaust system, and I would still have a 200,000-mile bottom end.

My game plan to minimize mistakes was to remove the blown engine first and place the two engines side by side, piecing things together on the new engine as I disassembled the blown one. Normally I wouldn’t be so cautious, but the photos should speak for themselves; this engine is intense. There are coolant hose connections and hard lines everywhere, a thicket of wiring, and many air pipes that either feed charge air, EGR, or vacuum. It’s something of an engineering marvel.

Removing the engine was a process, as well. The drivetrain is wide and weighs more than 600 pounds, so it would have been difficult to fish out from the top. I don’t have a lift, so removing it from the bottom wasn’t an option. I had to remove it from the front by disassembling the front clip and bringing it straight forward with an engine hoist.

It wasn’t too bad, as the main engine harnesses terminate at the driver’s side headlight, and there are three engine mounts: one on each end of the engine and gearbox and a dogbone mount at the bottom of the engine. A V-band clamp secures the exhaust to the downpipe, and a thin clip holds the DSG cable to the gearbox. Most coolant lines are self-contained except for the lines to the reservoir and radiator, which are held in with clamps and clips respectively.

The electrical connectors generally index to one another in a specific way, making mixed-up connectors almost impossible. Hindsight makes things very clear, and if I were to do it all over again, I would take the time to label every connector clearly. I did not, and I trusted that every connector would be unique, which presented difficulties once the new engine was dressed and ready to be installed. More on that later.

Fully dressing the new engine was a tedious task, considering the sheer acreage of cooling lines, turbo, exhaust, wiring harness, and the swap of the heavy dual-clutch gearbox. I peeled everything off the old engine in a way that made it easy to transplant onto the new one, but there were still a dozen coolant hoses to connect. Once I pieced everything together with a new timing belt and water pump, the task of offering the engine and gearbox back to the car felt a bit more daunting, but it came together nicely.

Putting the car back together went smoother than I could have hoped. Everything fell into place until the first start. I had a flashing glow plug light and a long crank to a hard start. My main issue was a crank position sensor no signal code. I pored over the factory service manual for a solution for weeks. I replaced the crank sensor and the wiring harness to the sensor at a $300 loss with no solution. The last chance I had was some wiring gremlin, but even with six weeks of spending a few nights a week searching, I just couldn’t crack the issue. All of the connectors seemed quite happy where they were.

I knew it was time to throw in the towel. I drank a humble tea and sent it to an independent repair shop.

They turned it away within a day. The tech was flabbergasted by my issue, so off to the dealership it went, with most of my hope depleted. But the dealer techs proved themselves incredibly competent. They found the issue in a few hours: After all that, the problem was traced back to mixed-up electrical connectors. Go figure.

It turns out that this generation of Jetta has identical 10-pin connectors for the passenger side headlight and a junction for the ECU. I had them mixed up. It also turns out that the connector for the intercooler water pump and crank position sensor were the same style of connector, another mixup on my end. I can only fault myself for not labeling each connector. I could have avoided a lot of pain and saved a lot of time and money if I had taken some extra time to future-proof myself.

All said and done, we spent a little more than $2,000 replacing the engine with a new timing belt kit and dealer diagnosis. It was fascinating to take a contemporary car apart and learn how it functions. Though it is complicated, I’m fairly confident in its reliability. It’s engineered well and the parts are fairly high quality. It’s shocking that Volkswagen sold this car for $22,460 in 2015 with this much technical complication.

I have my dirty diesel back on the road with a nicely worn-in engine for much less than the average dealer markup. It still gets 600 miles out of about 14 gallons, it’s still very quiet and comfortable, and it’s also my favorite Volkswagen in my fleet. Forever is a long time, but this is something I have no reason to sell.

This is my permanent and most excellent beater, and I could never buy a new version of it again.