The rotary engine is not quite dead. Despite it last making a sports car experience in the Mazda RX-8 just under a decade ago, the oddball triangular engine has an unbelievably strong cult following with folks still developing and making huge horsepower with them. One of the leaders of that cult is Rob Dahm, known for building a 1,200 horsepower four-rotor all-wheel-drive FD RX-7, and he’s building the biggest rotary engine ever: a 12-rotor marine engine.

For the uninitiated, Wankel engines are colloquially known as rotaries and typically come in two, three, and four-rotor configurations. They’re known for huge power density from miniscule engine displacements, especially when turbocharged. In its day, the FD Mazda RX-7 made 286 hp from 1.3 liters using two rotors force-fed by twin turbos. That engine was known as the 13B-REW. The next step up would be the three-rotor 20B engine from the third-generation Mazda Cosmo luxury coupe, which made 300 hp from 2.0 liters using very little boost pressure. Then the long undisputed king of rotaries was the R26B prototype four-rotor engine that gave Mazda the win at the 1991 24 Hours of Le Mans with the Mazda 787B. That made 900 horsepower from 2.6 liters.

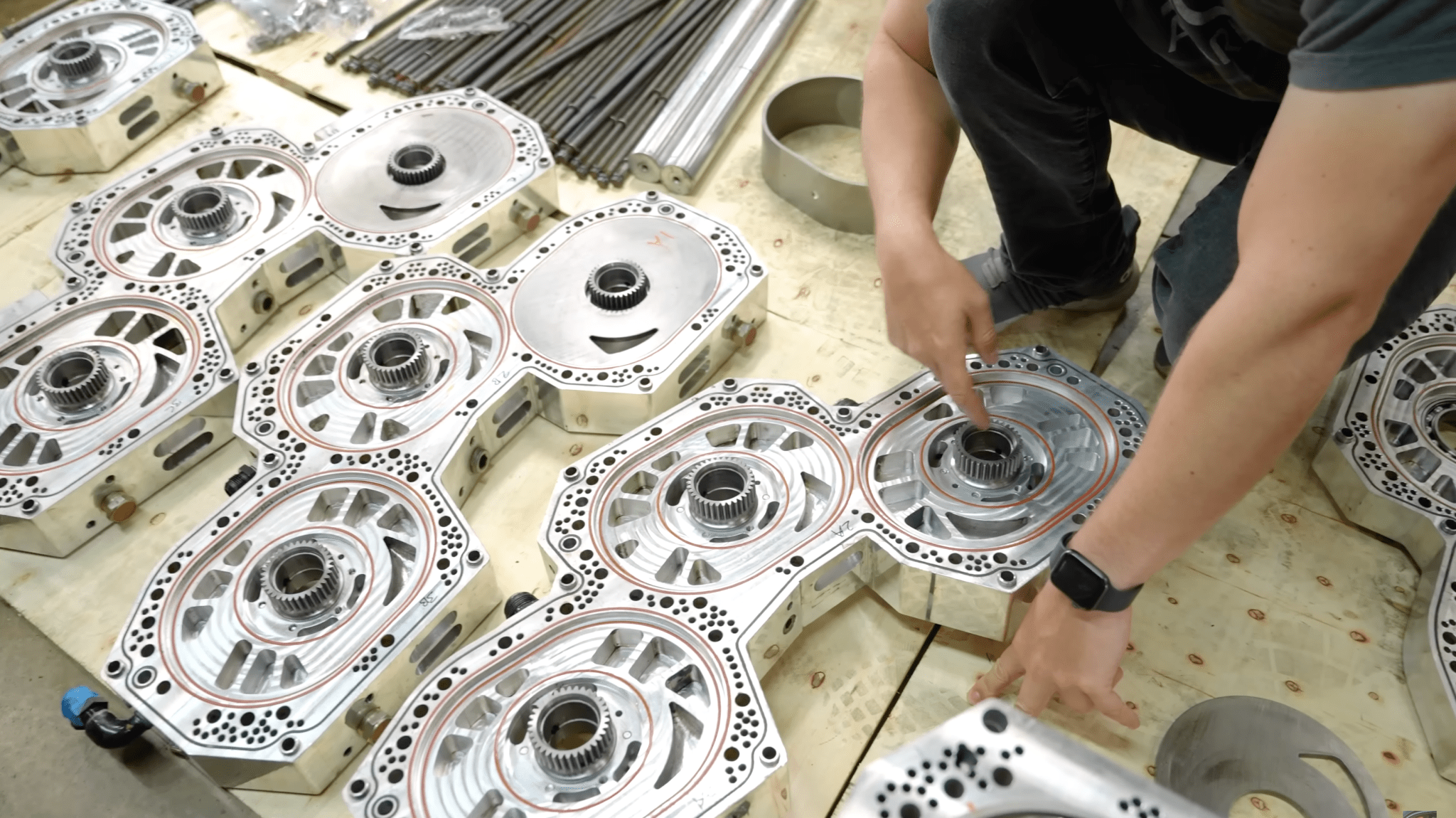

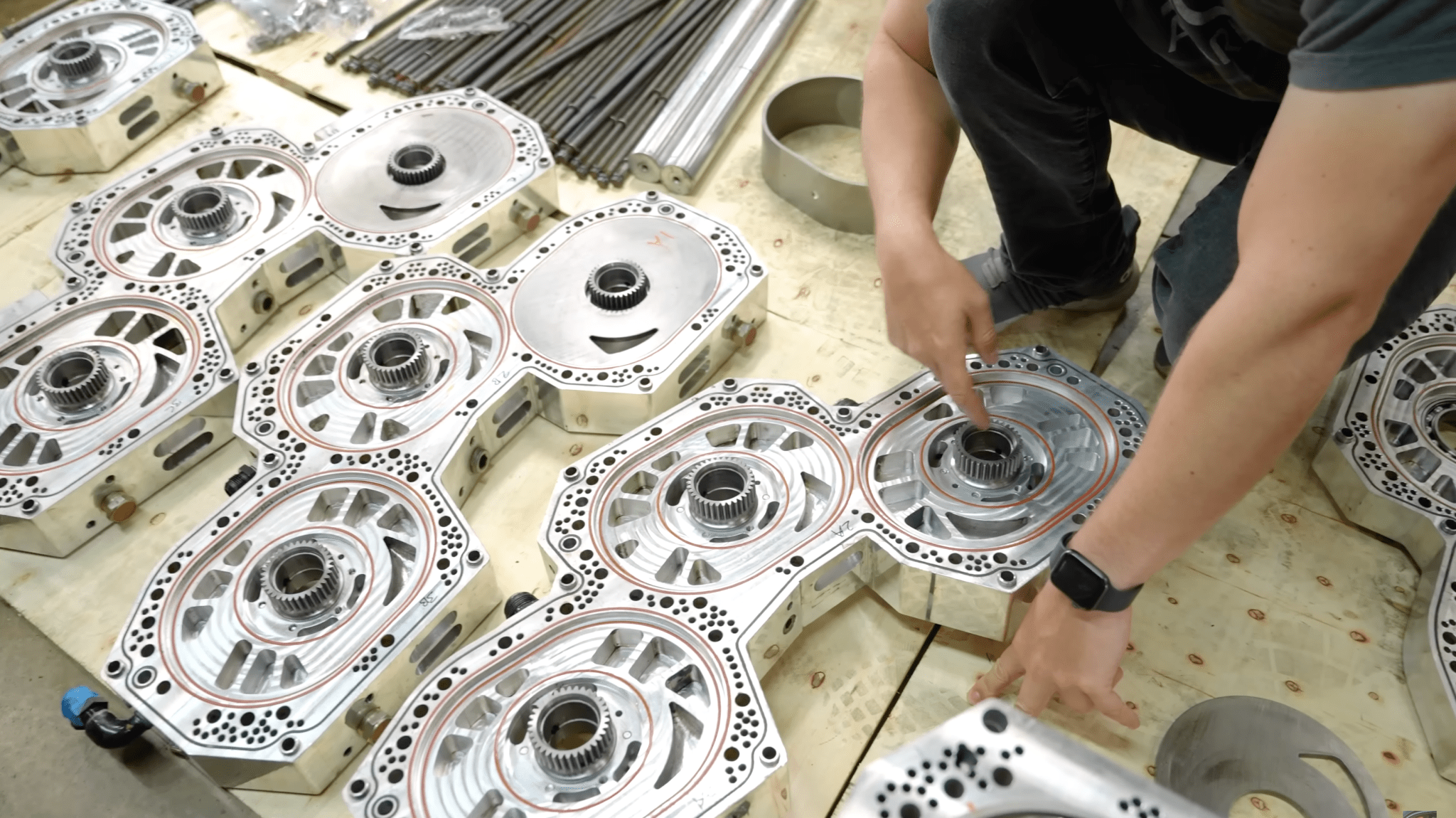

That’s where rotary engines hit a practical wall. Because of how rotary engines are designed, rotors are effectively stacked together like a sandwich. All three of the aforementioned engines are lengthened versions of themselves to fit the extra rotor, which means rotary engines get impractically long after four rotors. Rob Dahm’s 12-rotor engine avoids this issue by effectively combining three four-rotor engines together in a V shape.

It’s a truly bizarre bit of home-grown engineering that was apparently made by a person from scratch using ‘40s milling equipment and some CNC machines in 2008. The three four-rotor engines all have their own eccentric shafts (rotary speak for crankshaft), but are geared together to unify power output. It’s also unique in that it uses 180-degree firing like a two-rotor engine, where most four-rotor engines fire 90 degrees apart.

While the initial work is impressive, Dahm still has plenty to do. Dozens of small details need to get sorted before the engine can be run in anger. The engine has run before, but failed, leading to the chain of events that put the engine in Dahm’s possession. But before he changes anything, Dahm is assembling the motor with a small team of people and running it as-is just to see what happens. I wish him the best of luck.

Got a tip? Email tips@thedrive.com