Watching things get made can be a greatly rewarding process. You might learn something about the the device that you were unaware of. Watching the assembly process can also help when you have to fix that something. Or maybe you just like to see metal get cast and milled. Here we have a turbocharger getting made, from casting to assembly.

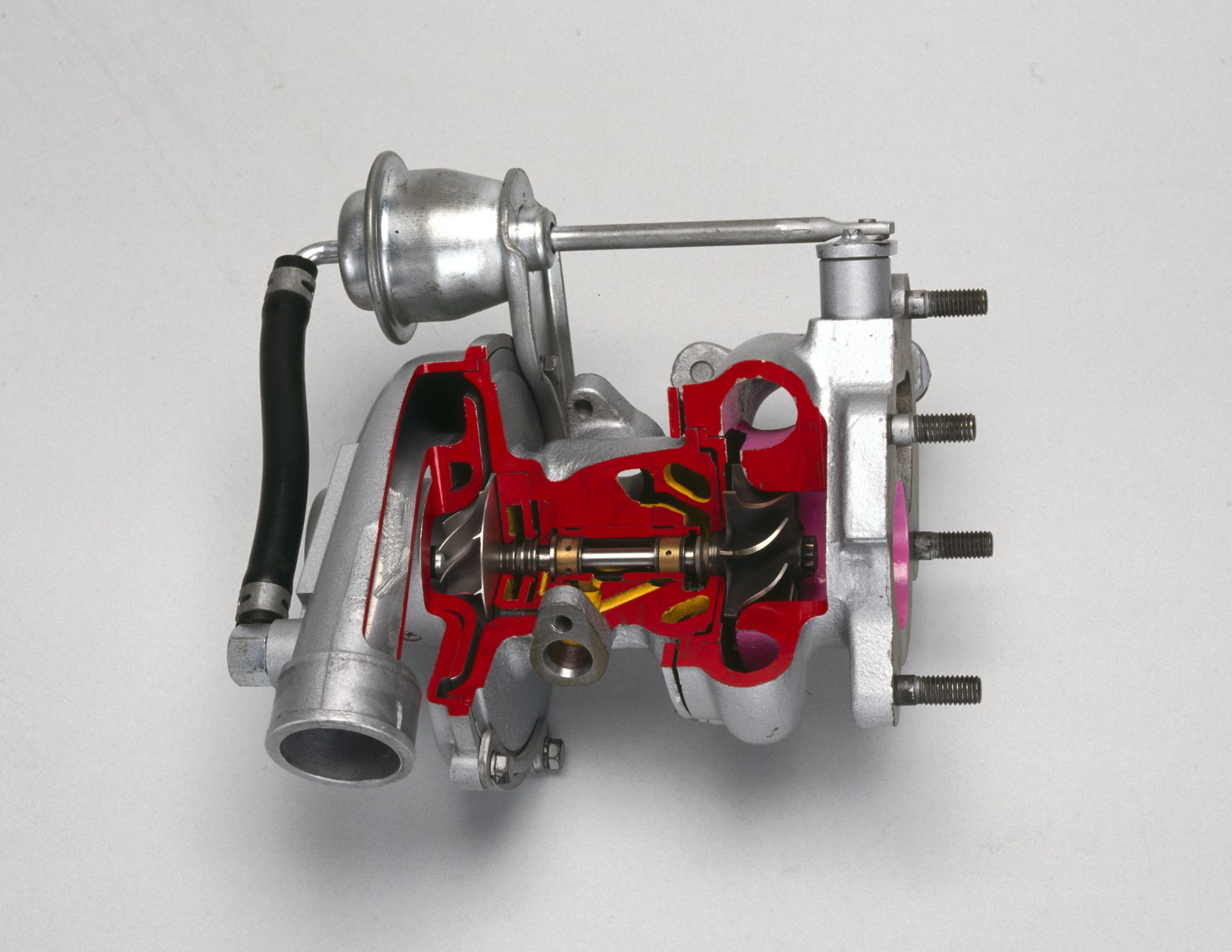

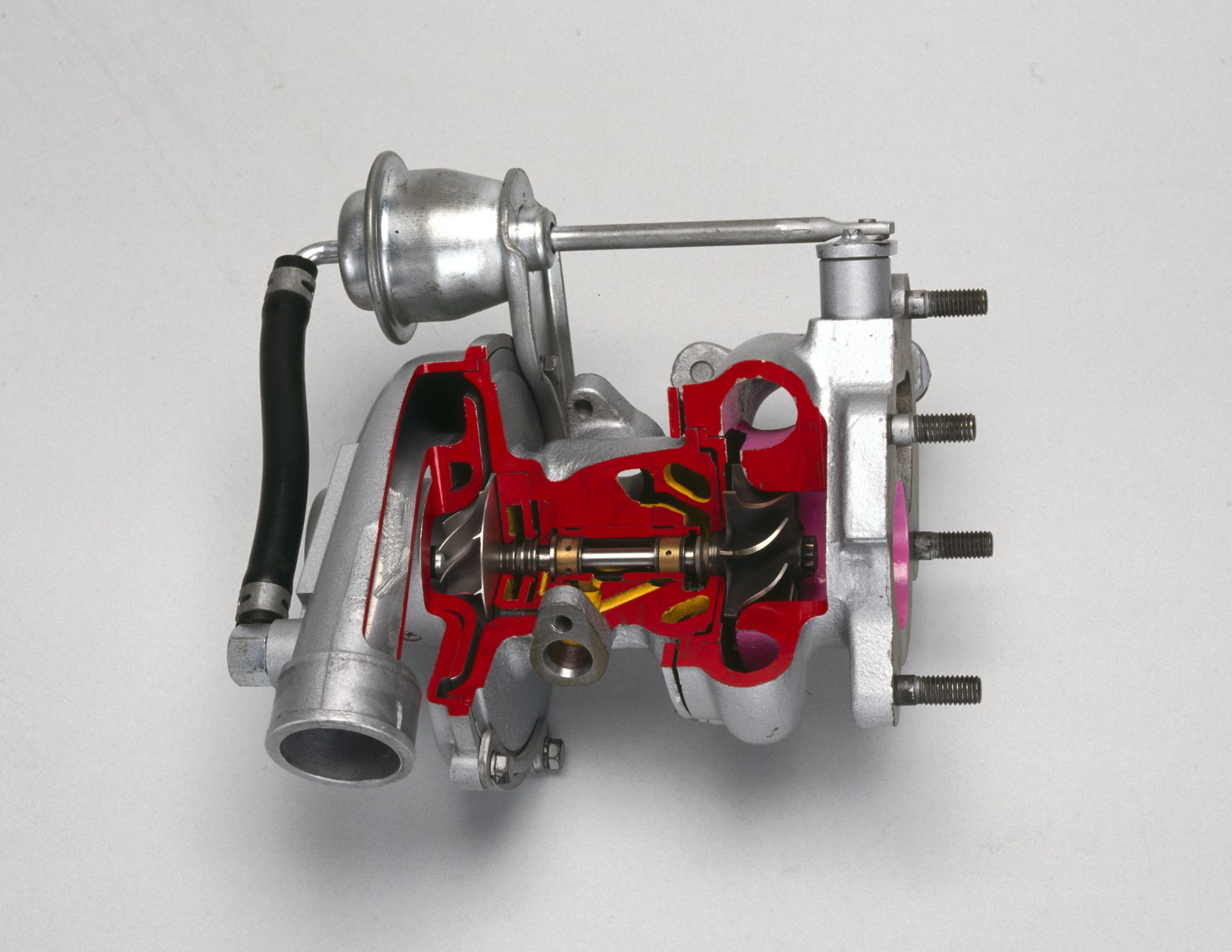

In case you are unaware, the turbocharger is quite an ingenious device. In the simplest terms, this is how turbos work. Exhaust gasses, which would otherwise be wasted energy are used to spin a turbine. Connected via a shaft through the device, that turbine spins an impeller that is located on the opposite side of the housing. The impeller compresses the air going in to the engine. That compressed air flowing in to the combustion chambers help the engine deliver more power, usually in a more economical way.

When a turbo is added to, let’s say, a four cylinder boxer engine, the car gets a nice boost in performance without the adding weight to the larger lump of metal powering the car. If set up properly, you can even achieve a significant gain in fuel mileage.

On the flip side, adding many turbos to something like the W16, which drives the Bugatti Chiron, delivers a very different result. The Chiron’s quad-turbo design gives the engine the air in needs to power the car to insane speeds while gulping down gas at rate that makes Hummers look eco-friendly.

Watching these little snail-shaped induction devices getting made gives you some insight as to exactly how it all works. It’s not black magic, it’s just physics. Even if you are a turbo expert, it’s still fun to watch these things go from sand molds, to aluminium casts, to milled and assembled machines.