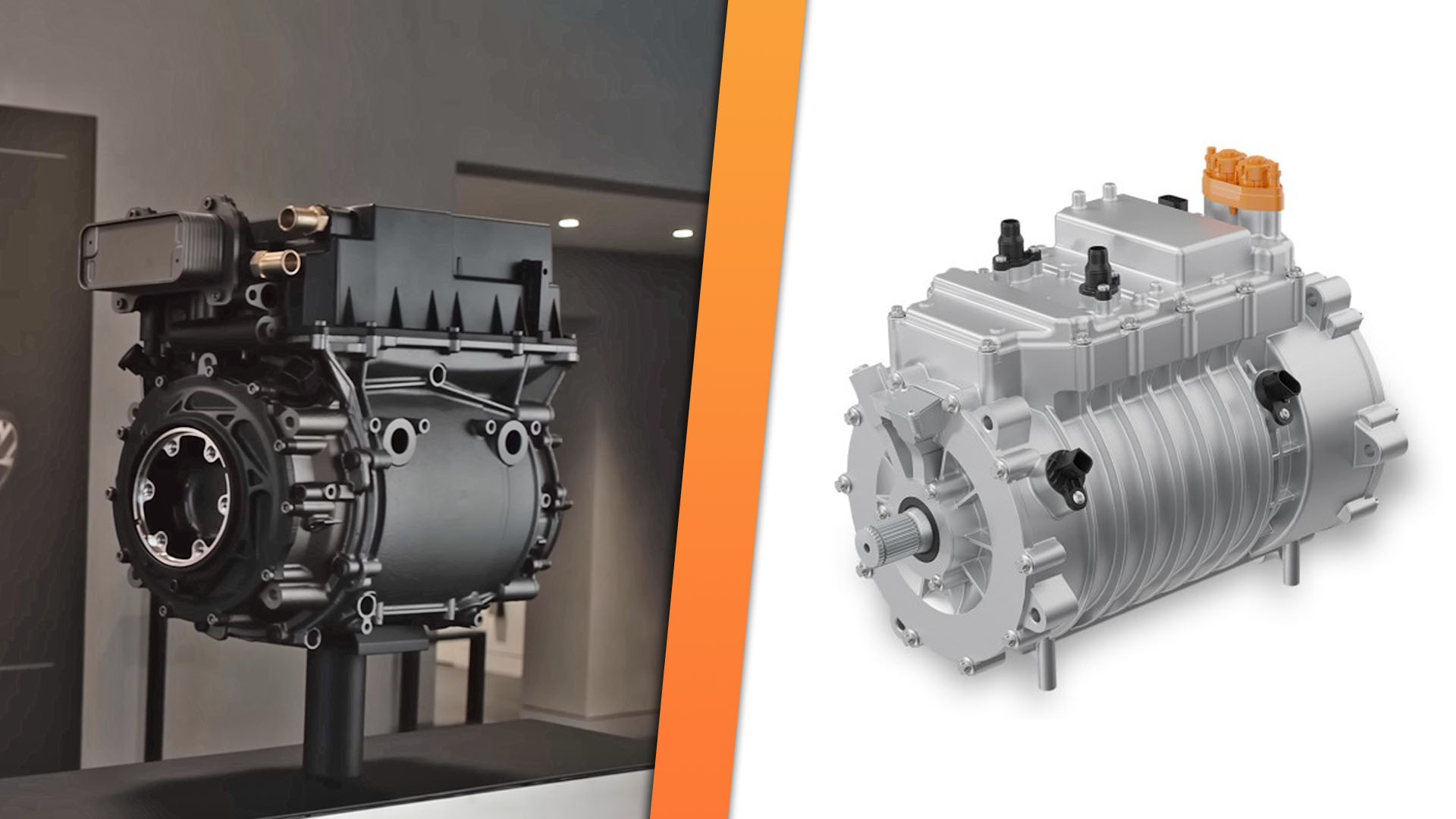

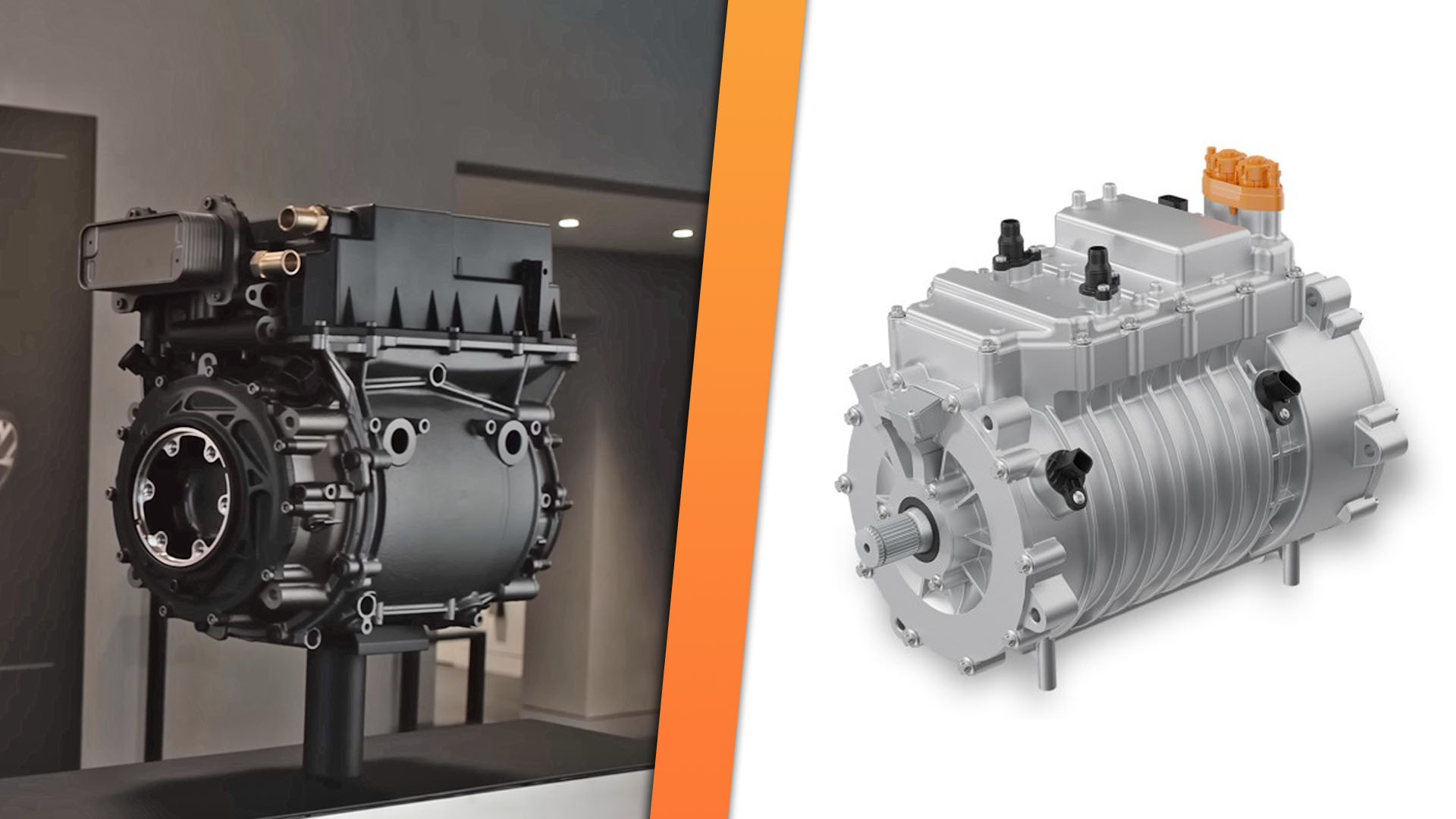

Massive German automotive supplier ZF has introduced a new permanent magnet-based drive unit for electric vehicles. Called the EVSys800, the compact, 163-pound assembly consists of a single radial flux electric motor combined with coaxial planetary reduction gears and a compact differential, very similar to what American automaker Lucid has developed and will likely provide to Aston Martin.

ZF’s new drive unit indicates that, despite being a cash incinerator as of late, Lucid’s core technology is far ahead of its competitors. ZF won’t sell this latest drive unit until 2026 and it produces less peak output—just 369 horsepower (275 kilowatts) as compared to Lucid’s 670 hp peak—despite operating at a similar voltage. The continuous output for the unit is likewise stated at just 276 hp. The German supplier is currently testing this drive unit in a Porsche Taycan, which it calls the EVbeat.

ZF has fallen short in terms of explaining its drive unit as compared to Lucid, which has published a number of detailed tech talks to walk people through how its hardware works in detail. That being said, ZF has provided some information about the device and a few images.

Most electric drive units consist of an inverter/controller, the motor itself, and a reduction drive to turn the high-speed, low-torque motor output into lower-speed, higher-torque rotation suitable for driving a car’s wheels. A differential is also included in single-motor cases.

The vast majority of automakers have an electric motor on its own rotational axis as compared to the car’s axle centerline. This allows for a simple reduction gear connected to a more conventional-looking differential, which drives the wheels. General Motors’ Ultium drive units work this way. ZF’s unit is similar to Lucid’s in the sense that a centrally mounted motor is on the same rotational axis as the reduction gears, which are planetary sets. A differential is also integrated along the same axis. This translates into a smaller case and can mean other optimizations in terms of component strength.

In Lucid’s case, it places lightweight differential spider gears inside of the electric rotor itself, which means they only experience the low-torque, high-speed force of the motor. This output is then reduced to high-torque wheel speeds.

ZF’s unit seems to work a little differently. It appears as if the planetary gear rotor is double-sided—capable of driving both inner planet gears and a smaller set of outer planet gears. This effectively makes it two planetary sets. It’s possible that by driving one set of these gears, which likely mount to their own carriers, that differential drive between the two sides of the unit can be achieved. The German company did not go into detail about how this works, stating only that “[t]hese gearsets not only generate the desired axle ratio, but also assume the fully integrated differential function.” An animation or something along those lines would definitely help here.

Outside of the mechanical parts, the power electronics are interesting as well. Similar to other new EVs, ZF is betting on higher voltages for more efficiency and greater power potential. The EVSys800 operates at 800 volts, as you might have guessed, and uses silicon carbide MOSFETs to translate DC power from the battery into three-phase AC for the electric motor. Silicon carbide MOSFETs are already used by the likes of Tesla and, yes, Lucid. They are capable of operating at faster switching frequencies at higher temperatures, which makes them ideal for high-power applications like a car. Other automakers use silicon-based MOSFETs which are more readily available but arguably not as capable in an automotive context.

The motor itself is also Lucid-like, going with thicker distributed windings that are “woven” into the electric motor’s three-phase stator. When it comes to stator windings, the compromise between copper use and manufacturing speed means you have to get creative, and ZF has done that here. It also claims that the rotor “does not need any heavy rare earths,” in reference to the permanent magnets embedded in it. This reduces cost and has the potential to streamline potential supply hiccups.

Along with all of this neat technology, an integrated operating system for an entire vehicle—at least as it concerns drivetrain efficiency—is offered as well. This unit integrates the control of other vehicle systems like HVAC to optimize motor conditioning for the sake of efficiency.

Altogether it’s an interesting drive unit that we’re very likely to see on future electric vehicles. Whether automakers will decide to plow ahead making their own drive units or purchase them from the likes of ZF is yet to be seen. Some with little in-house EV experience may elect to buy a complete package from a supplier. Other, larger companies like Ford, GM, and Mercedes will likely elect to build their own or acquire companies that build things like motors and inverters.

Got a tip or question for the author? You can reach them here: peter@thedrive.com