One of the most important components of any car is its suspension. It’s what helps to absorb imperfections in the road—both big and small—and provides a comfortable ride. Today, nearly every vehicle on the road today uses some form of metal spring to provide that cushion, but that may soon change.

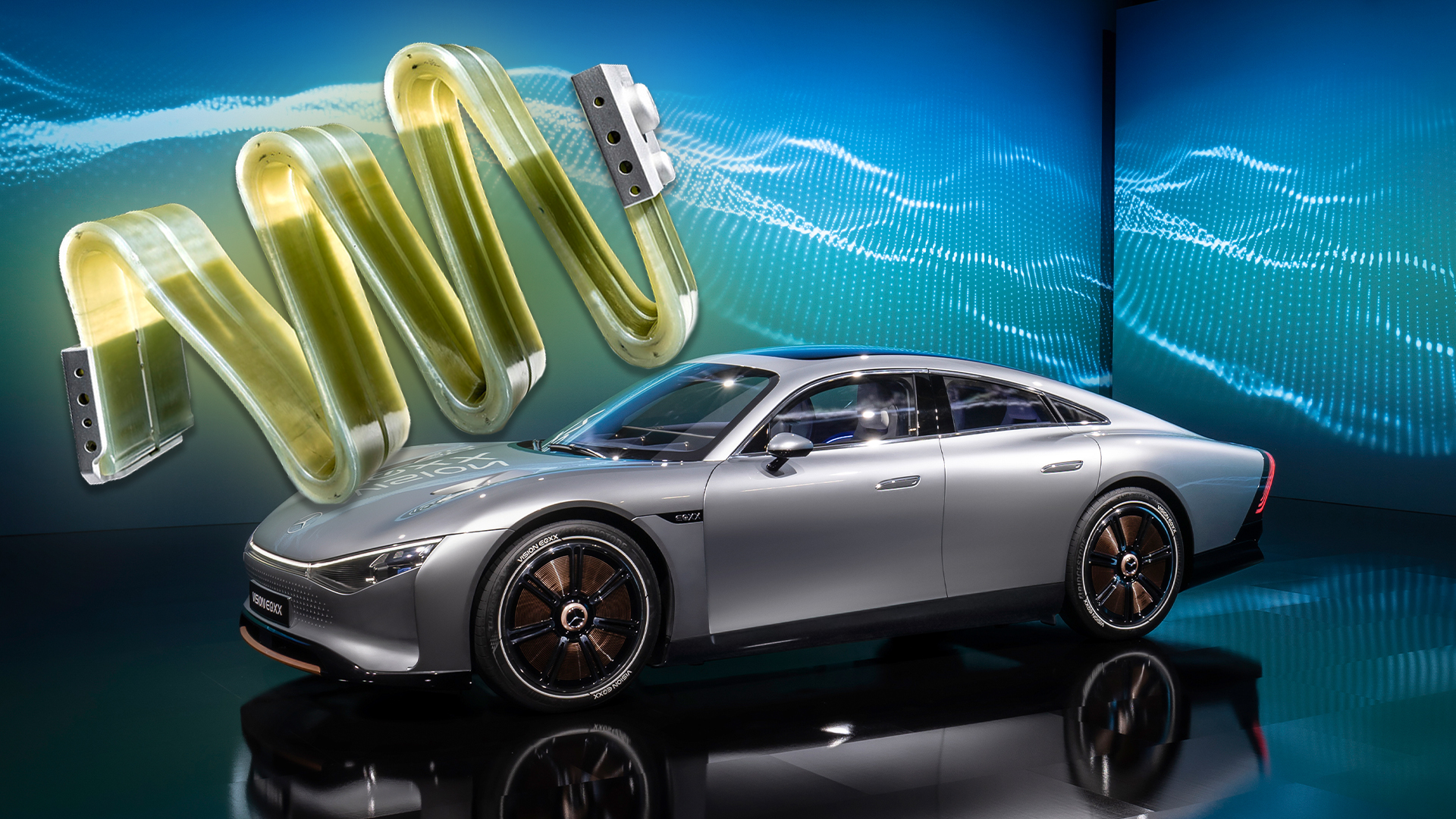

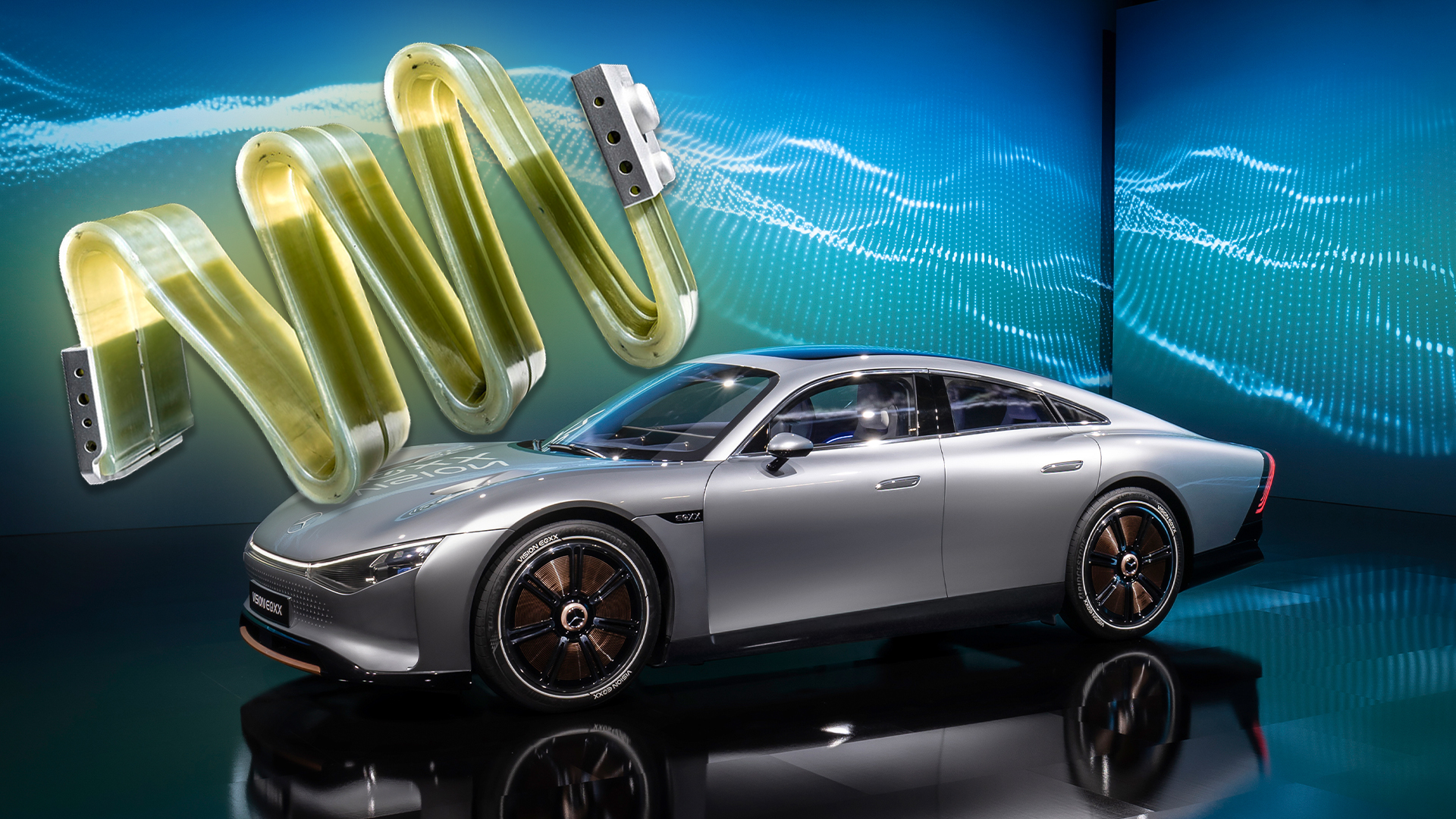

Rheinmetall, an automotive supplier in Düsseldorf, Germany, developed and tested a prototype spring made from fiberglass-reinforced polymer. After an intensive testing program, Rheinmetall said in a statement that a “premium” automaker placed an order for these springs, meaning that they may one day soon be on a car near you.

In case the words “plastic” and “spring” don’t bode well with you, Rheinmetall offers some reassurance. The company notes that it offers superior corrosion resistance versus traditional metal springs, offers high inherent damping (absorption of noise, vibration, and harshness), as well as “outstanding” fatigue strength, which means a vehicle could continue driving in an emergency.

While Rheinmetall hasn’t publicly revealed which automaker placed the order, there is one possibility that comes to mind: Mercedes-Benz.

The technological marvel that is the Mercedes-Benz Vision EQXX concept made use of quite a few interesting bits not typically seen on road cars, including Rheinmetall’s special polymer springs. At the time, Mercedes said that it worked with Rheinmetall to develop the part, noting that it offered a significant reduction in weight—something important in electric cars looking to squeeze out some extra range. Mercedes doesn’t note an exact figure, but Rheinmetall calculates an unsprung mass reduction of around 75 percent versus traditional coil springs.

We reached out to Rheinmetall and Mercedes-Benz for a comment, but neither company immediately responded.

Mercedes also has a history of using some rather unorthodox spring designs (just like engineering behind the W124 4matic’s front coil springs needed to clear the front axles). That being said, it’s not hard to picture this newfangled setup underneath a ‘Benz, of all the luxury manufacturers.

Rheinmetall mentions in its statement that it presented the spring publicly “in a prototype testbed vehicle” during a partnership with an unnamed automaker. Since then the automaker put the part through a rigorous testing program and accepted the part following successful trials. The parts supplier says that it is also working with other manufacturers since its initial testing, meaning that these plastic springs may be more than just a one-off application should the tech catch on across the industry.

Got a tip or question for the author? Contact them directly: rob@thedrive.com