From airbags to in-car perfume spritzers, Mercedes-Benz is always eager to adopt new features. But to make vehicle production more environmentally friendly, the automaker is looking backwards instead of forwards.

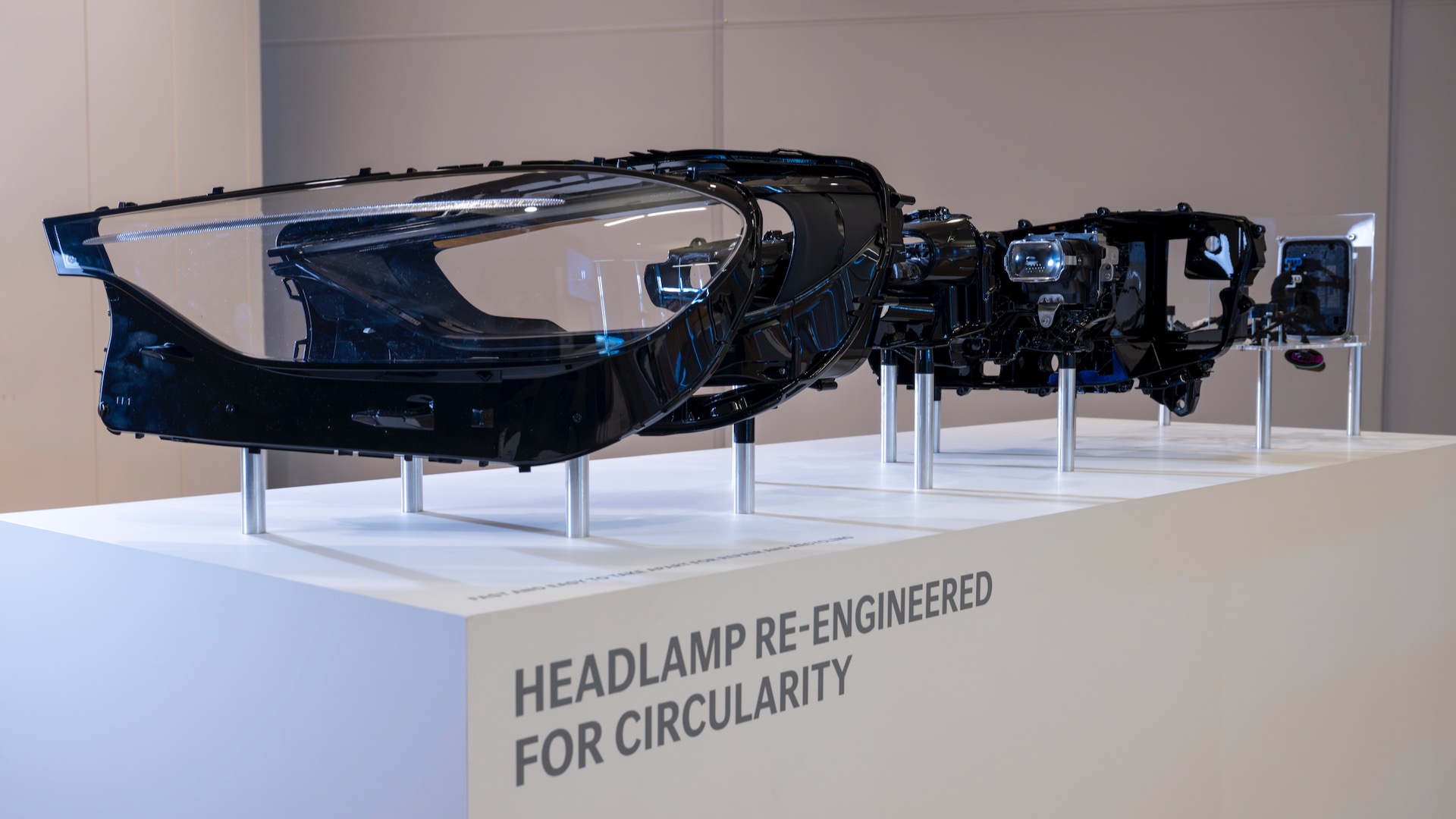

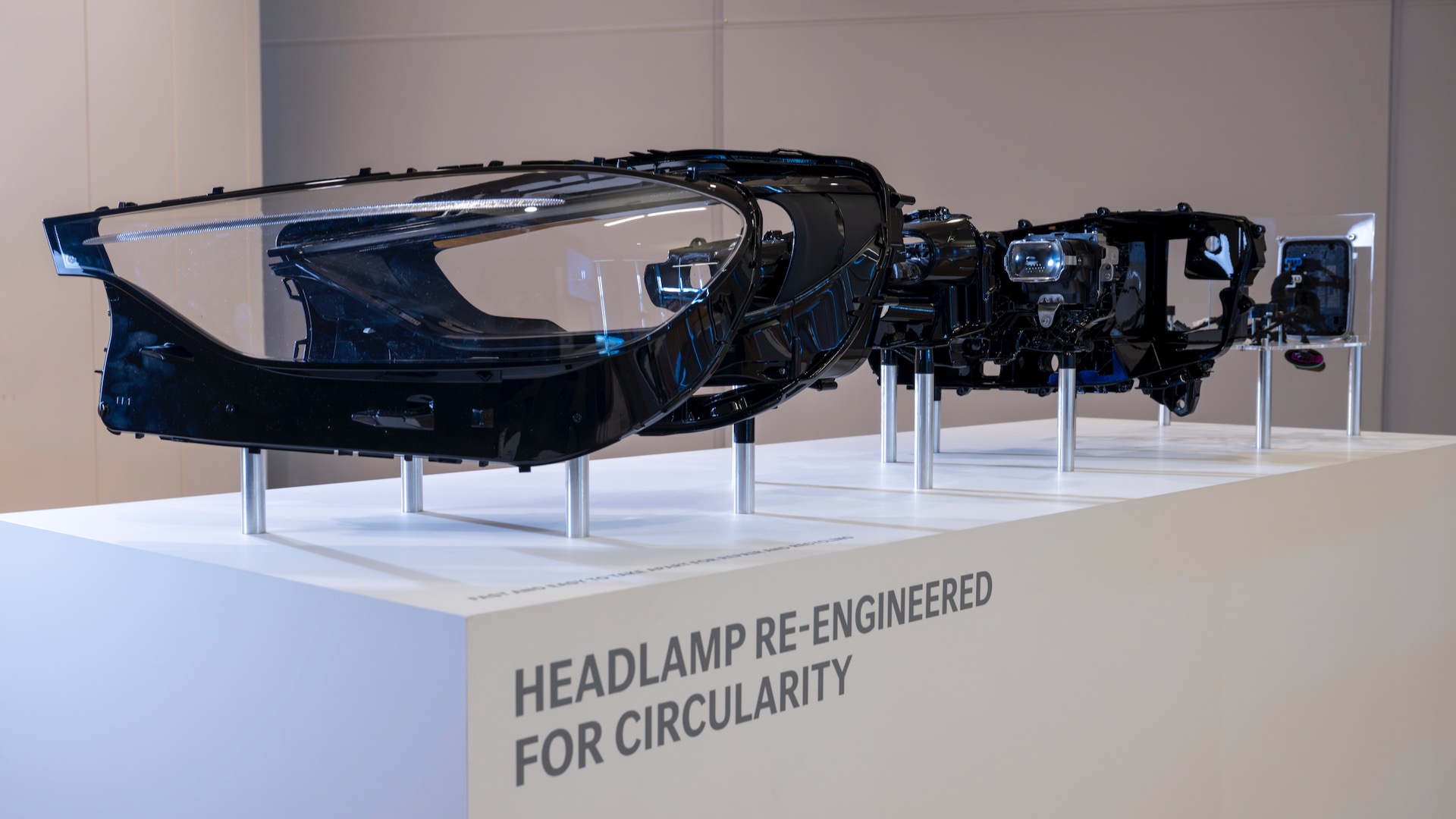

Mercedes’ current practice is to glue individual components together when assembling headlights. As part of a sustainability initiative called Tomorrow XX, the automaker is looking at replacing the glue with screws. This more basic approach allows those individual parts to be more easily separated, Mercedes said in a press release. That makes replacement easier, which avoids junking an entire headlight because of one bad part. That could significantly extend a headlight’s lifespan.

Headlight lenses are vulnerable to damage from stone chips, so being able to unscrew one and replace it with a fresh piece could lead to fewer headlight replacements. In addition to making life easier for owners, this would also reduce carbon emissions because there’s less need to manufacture new headlights, according to Mercedes.

The automaker also hopes to make each part of future headlights out of a single material to aid recycling, as composites of multiple materials, such as mixed plastics, are harder to break down and turn into usable raw material. Materials recovered from old headlights could then be used in new ones. Mercedes believes it can nearly double the use of recycled materials compared to current headlights, which would cut carbon emissions roughly in half.

Mercedes is also looking into simpler assembly processes for other parts. For interior door panels, it hopes to replace ultrasonic welding with thermoplastic rivets that are easy to undo, allowing the door panel to be disassembled and individual materials separated for recycling when a car has reached the end of its lifespan.

As for actual uses of recycled materials, the redesigned CLA-Class has a wiper fluid tank made from 100% recycled polypropylene and bumpers made from 25% recycled materials. In the future, Mercedes may also use old tires to make synthetic leather and sound-absorption material, and engine mounts made from recycled airbags, if current experiments pan out.

All of this aims to create a “circular economy” in which new cars are made primarily from materials recovered from old ones, helping to conserve resources and reduce emissions. Mercedes isn’t the first automaker to buy into this concept—BMW designed an entire concept car around the idea—but that’s for a good reason.

The climate impact of cars doesn’t just come from their tailpipes; manufacturing and resource extraction are part of the problem as well. The humble screw may not be a technological marvel, but if it can make car production more sustainable while also letting owners more easily handle repairs themselves, it could be the next big thing.

Got a tip? Hit us up at tips@thedrive.com