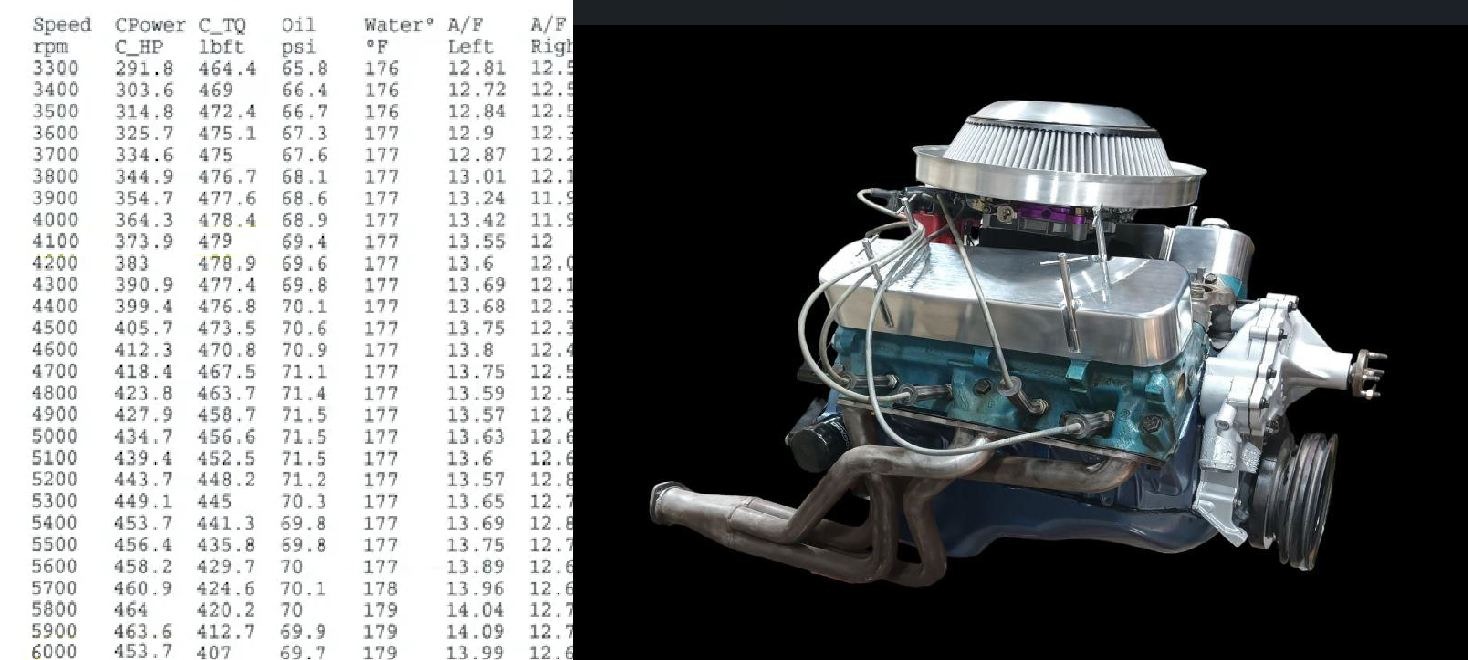

You may or may not know that Pontiac built a 301-cubic-inch V8 from 1977 to 1981. Although it was touted as lighter than its Chevrolet small-block counterparts, it was far from a barnburner. Just imagine a 4.9-liter V8 making only 140 horsepower—that’s down 10 hp compared to a new Honda Civic. Ted Fox saw potential in the old GM power plant, though, and he somehow managed to squeeze 464 hp out of the lazy old lump without any boost.

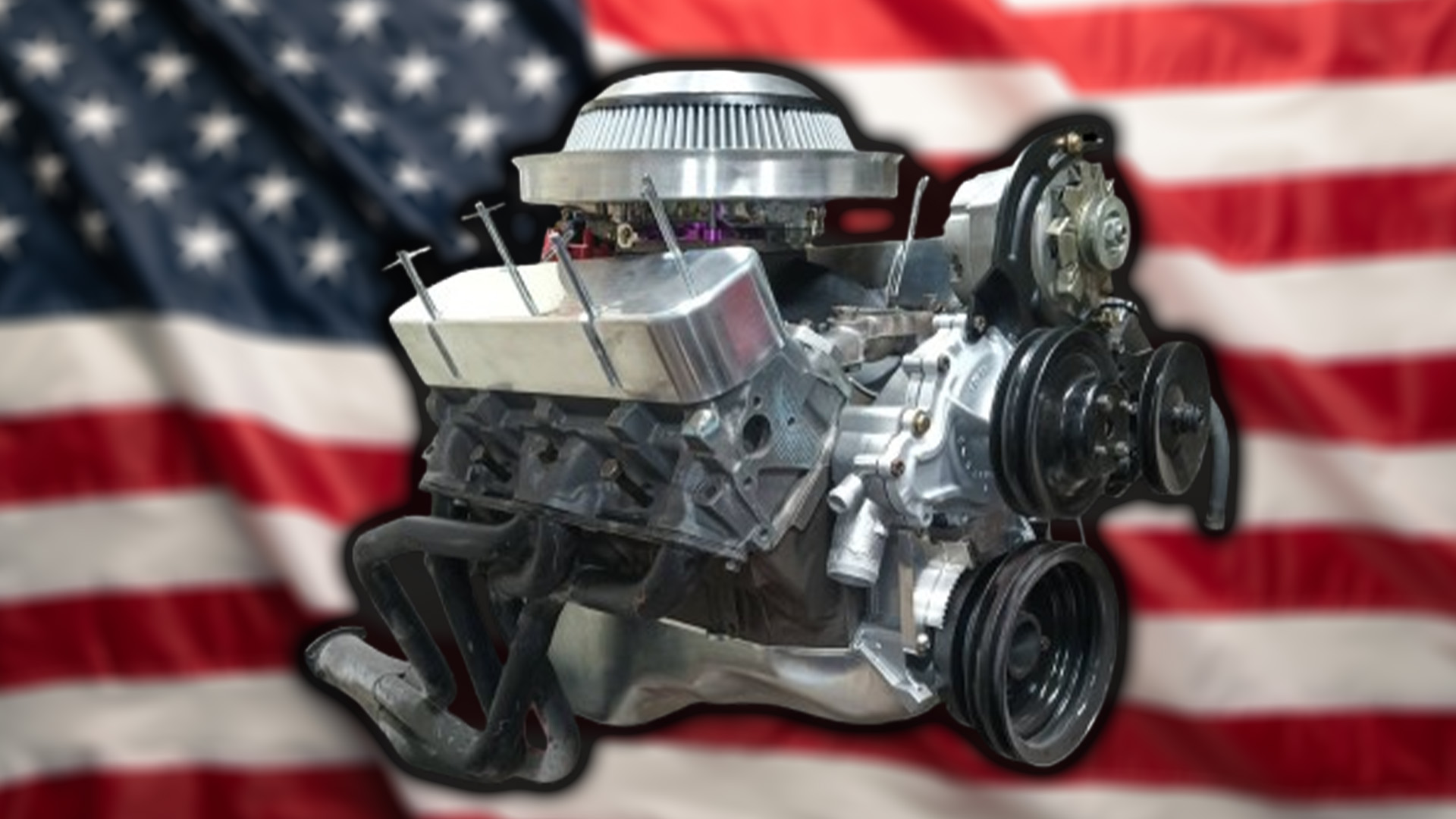

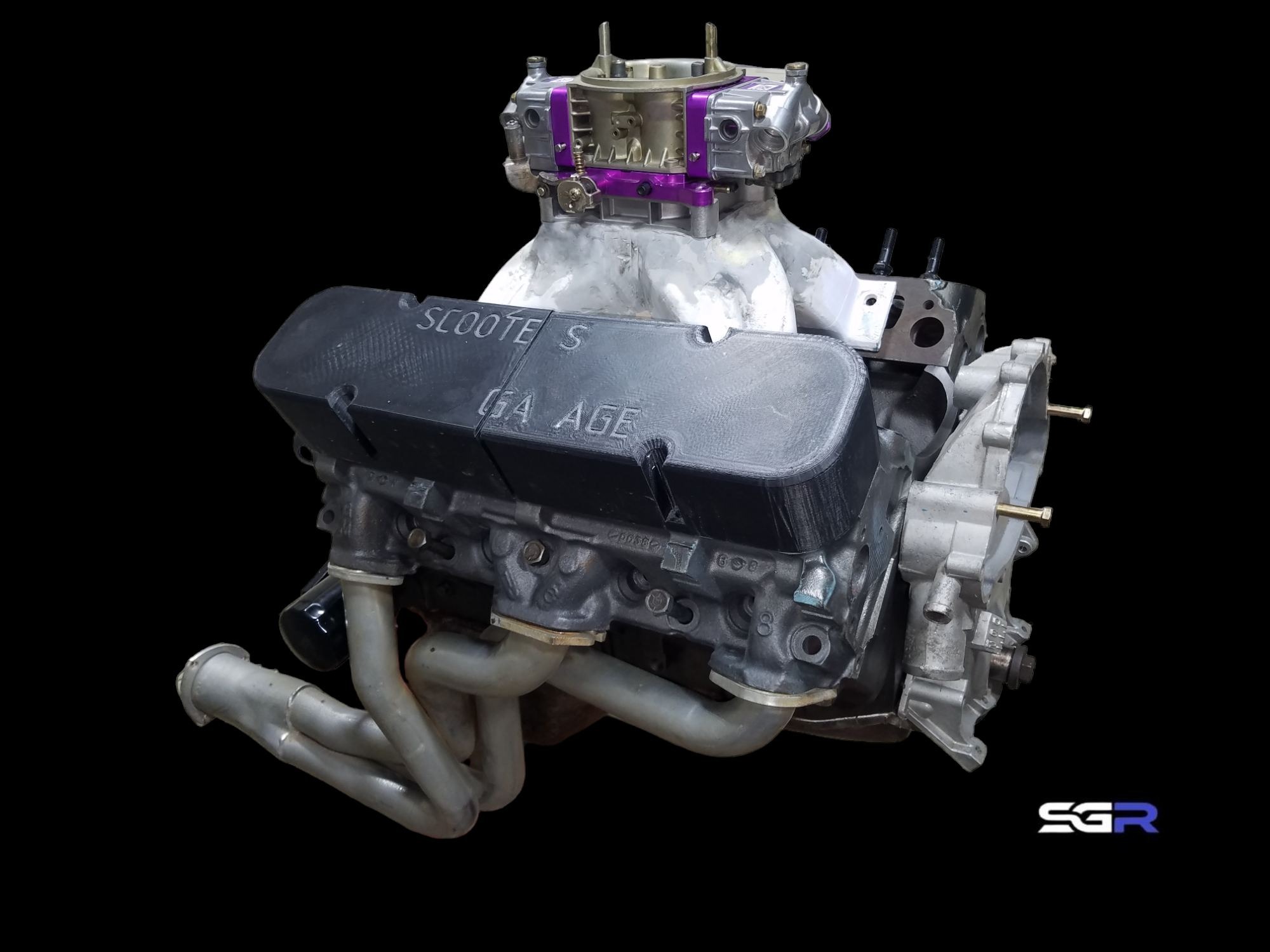

Fox did this at his shop, Scooter’s Garage in Lancaster, Texas, with help from some thoroughly modern manufacturing methods. Rather than installing time-tested power-adders like a supercharger, he utilized 3D scanning and printing to make fundamentally better parts, mainly for the top end. Fox used these 21st-century tools to develop cylinder heads and an intake manifold that flowed way better than stock, along with a few other odds and ends that more than tripled the engine’s horsepower.

As he explained it to me over the phone, Fox was working on a 301 Pontiac for a customer when his friend walked in. “I bet you can’t get 200 hp out of one of these things naturally aspirated,” he quipped. Fox took this as a challenge and promptly made 220 hp on the first dyno pull. The bet continued, turning into a double-or-nothing challenge to make one hp per cubic inch. Everything snowballed from there into what Fox has today: an engine he calls the OG Mule.

Fox got in touch with Jeremiah Heidner, a 3D scanning and printing specialist at Heiphus. The two of them performed a few scans on the stock 301 heads, and after deciding to do away with the factory siamese-port setup, they sent off some intake manifold designs with traditional porting. The prototypes were printed in a way similar to how GM and other manufacturers develop new parts for their engines.

The result was roughly 405 hp on the engine dyno. Clearly, things had gotten serious with Fox’s pet project. This is when he decided to go “knee-deep” into the short block by upgrading the pistons, increasing the compression, and installing a custom camshaft that he described as “way scienced out.” Nice.

Three-dimensional printing continued to come in handy as they made several permanent parts via additive manufacturing. Not only did they develop three variations of the intake that are 3D-printed, but they also developed the four-barrel carb adapter and the timing pointer, which helps advance the 301’s factory timing from 24 degrees to 36 degrees.

“On the 301 intake alone and in the cylinder head, we probably have 1,500 hours of flow testing,” Fox told me. “What we found is that it would cause this weird turbulence in the inside radius. It would literally ski jump and slam the outside wall of the runner, causing turbulence and ultimately impacting power. So we incorporated that into the new design. Even though it kind of looks like a factory intake, it actually has about three or four different little improvements.”

Fox ultimately tested the 301 on three different dynos to prove it’s capable of making 464 hp and 479 lb-ft of torque consistently. During those runs, the engine was running the 3D-printed valve covers, timing pointer, and intake manifold. It’s really intriguing to me because although the parts-making methods are modern, the approach is still a throwback to how engine building used to be. You know, back before you could tweak software and force more air and fuel through cruddy parts to make bigger power.

The project has turned into an even bigger operation, as Fox has designed three unique intake manifolds for the Pontiac family of V8s. He calls it the Tiger Cub Initiative, in reference to an old Pontiac ad campaign in which the automaker compared the GTO’s engine to a tiger. Meanwhile, other sporty cars were just “pussycats.” Have a watch:

Currently, Fox is working on bringing three different intakes to the hot-rod community: the Tiger Cub 1, which maintains the factory siamese port design but corrects flaws like the turbulent flow; the 2FI, which accommodates fuel injection and nitrous while being loosely based on an old Holley design that was disregarded decades ago; and the 3FI, which is akin to the old “Warrior” intakes designed by drag racing legend Doug Nash. Fox even talked to someone involved in the original development and production of the Warrior intake, who provided some super valuable input.

All in all, it’s an extremely slick project that went further than Fox could have imagined. I was stoked to learn about it, and hopefully, you are too. They don’t hardly make ’em like this anymore.

Got a tip or question for the author? Contact them directly: caleb@thedrive.com