To butcher a line from an old musical—it seems that at Great Britain’s best-known luxury carmaker, tomorrow belongs to 3D. Exotically-named Rolls-Royce CEO Torsten Müller-Ötvös said the fabled luxury carmaker could wind up using the same technology we at The Drive use to whip up goofy toy cars to create the exteriors of future custom models.

“We have done some 3D printing,” Müller-Ötvös said to Car and Driver at the launch event for the all-new 2018 Phantom, adding: “I think that our long-term goal is to print bigger parts; maybe even bodies are possible.”

But while 3D printing offers the potential to create complex body panels with greater ease than traditional methods, the goal of these 3D-printed Rolls-Royce bodies wouldn’t be to do anything as plebeian as lower prices. In fact, according to Müller-Ötvös, the carmaker would rather look to use it to help create bespoke project cars for its wealthiest clients. He cited the $13 million Rolls-Royce Sweptail as an example of the sort of custom vehicle the carmaker has plenty of demand for, but simply hasn’t been able to crank out very easily.

“That was a very successful experiment, but it took us four years,” he told C/D. “The market potential is not the problem. The challenge is to make it happen.”

One-off and super-limited-run special models have become an increasingly important part of the business model for high-end carmakers in recent years, as they seek to find ways to stretch their already-expensive model ranges further into the stratosphere. Thanks to a sky’s-the-limit approach to options and features, buyers can easily push the window sticker on “regular” super-luxury cars to double their base price or higher—and that’s before even diving into the realm of custom bodywork, which can often send the cost of a car into seven-figure territory.

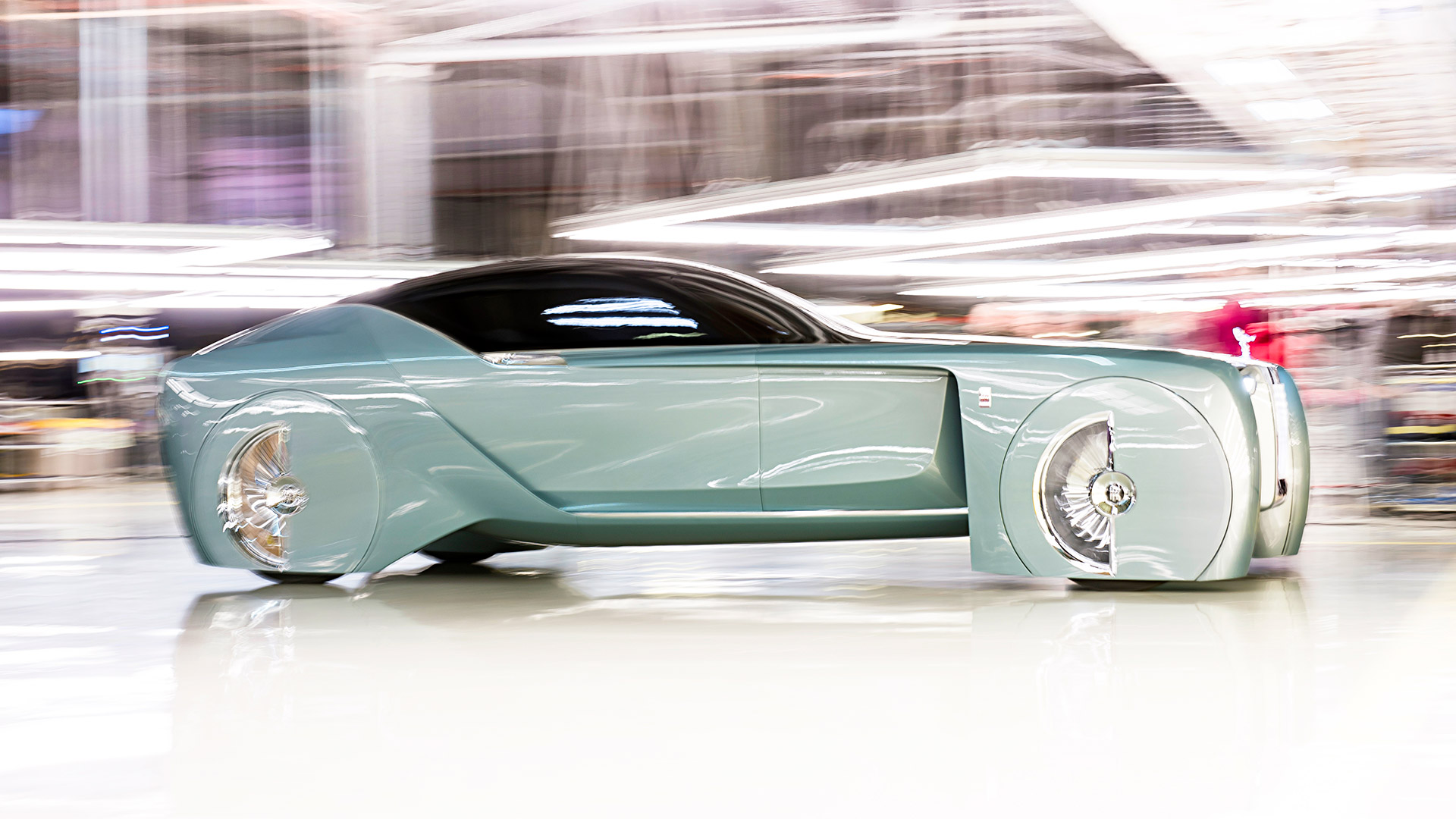

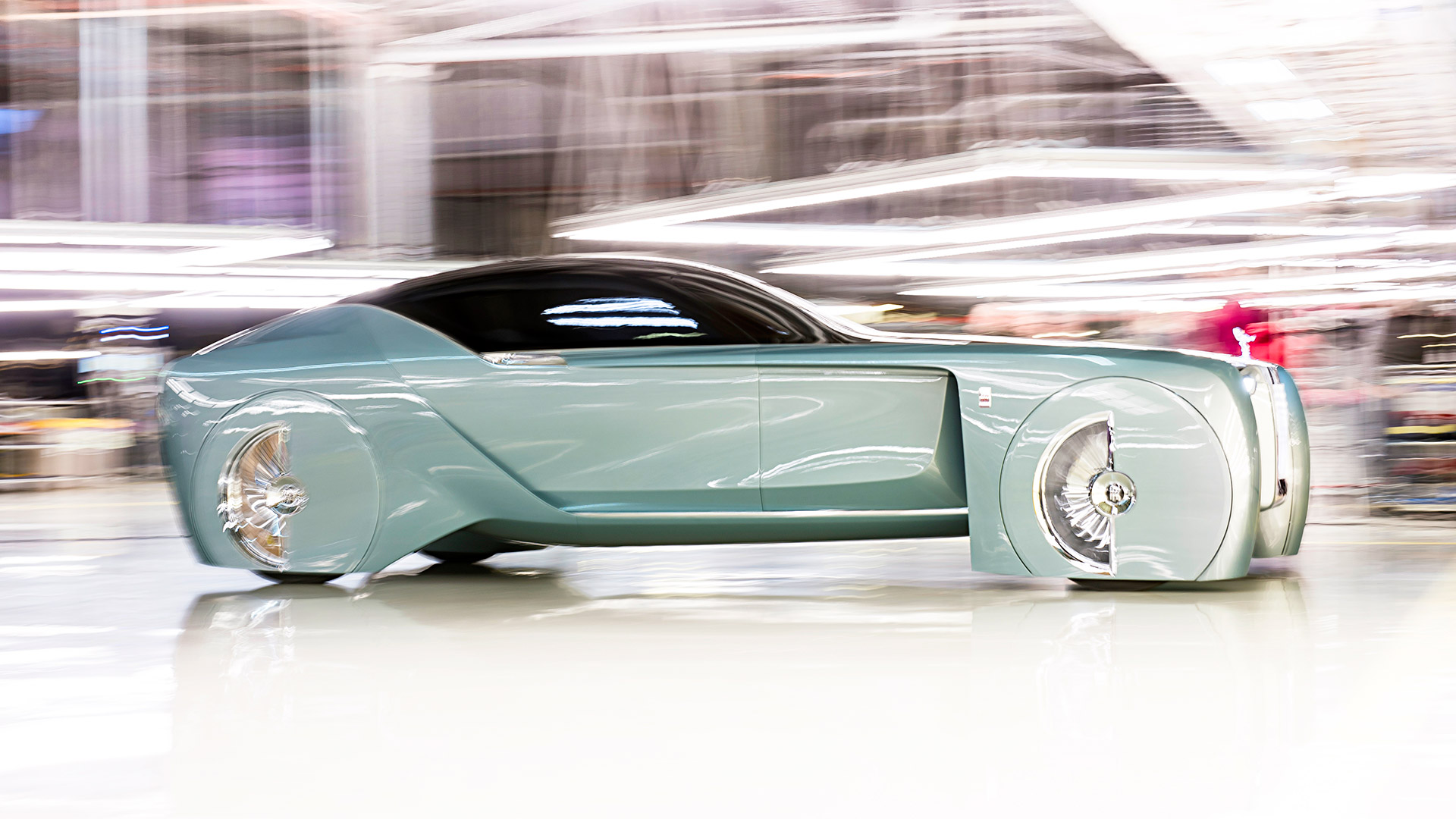

Pictured: Rolls-Royce Vision Next 100 Concept