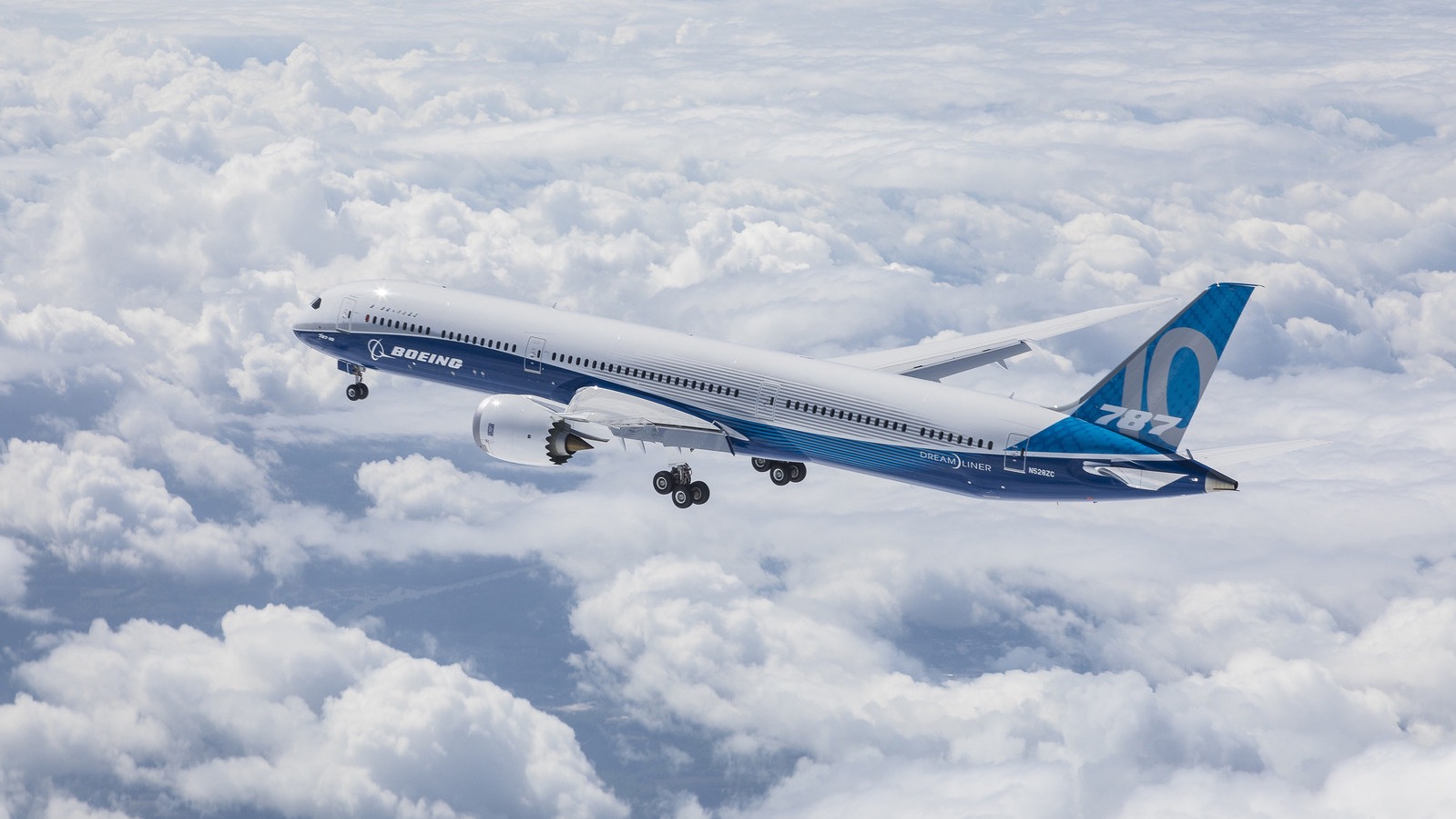

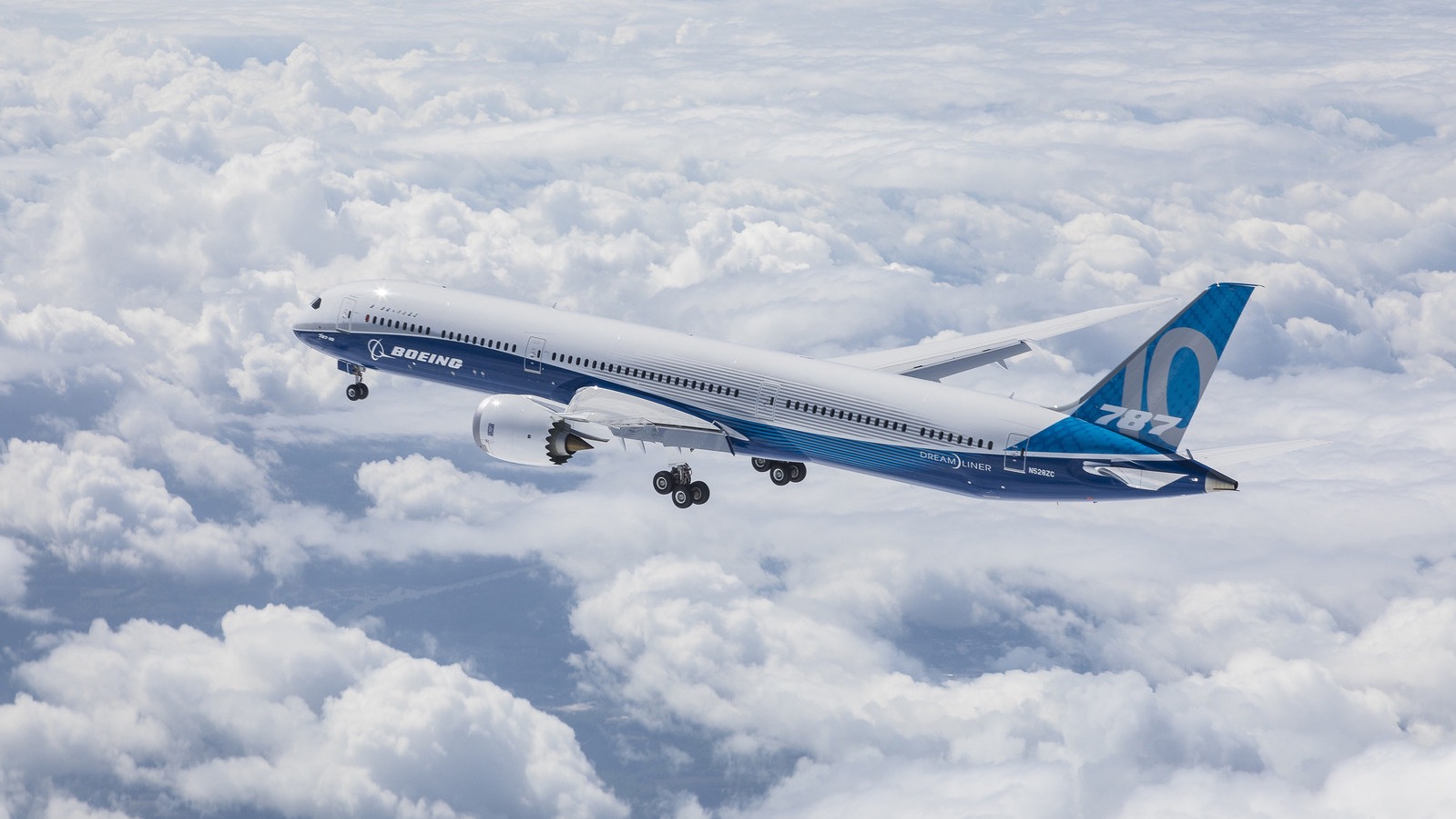

Boeing will use 3-D-printed titanium parts in the structure of its 787 Dreamliner. The company is contracting with Norse Titanium AS to print parts for the massive airliner, and Norsk claims that will save Boeing a lot of money.

“This means $2 million to $3 million in savings for each Dreamliner, at least,” Chip Yates, Norsk’s vice president of marketing, said in a phone interview with Reuters. Production of 3-D-printed parts is expected to ramp up next year, as Boeing tries to reduce manufacturing costs and increase profitability on the Dreamliner.

Titanium is more expensive than the aluminum used in most aircraft. It accounts for $17 million of the $265 million cost of a Dreamliner, according to Reuters.

Boeing has not confirmed the cost savings estimates mentioned by Yates. It builds 144 Dreamliners in a typical year, and only recently turned a profit after accruing $29 billion in production-related losses.

Yates said Norsk has been working with Boeing for more than a year to obtain Federal Aviation Administration certification for four 3-D-printed titanium parts. He said Norsk expects the agency to sign off on the material properties and production process for those parts later this year, which will “open the floodgates” and allow the company to produce vastly more parts for the Dreamliner. Only at that point will the projected millions in cost savings be realized.

Yates said literal tons of material on a Dreamliner could be 3-D printed. Norsk and Boeing claim the parts they plan to use are the first printed structural components used in an airplane, meaning they will actually bear the stress placed on the airframe.

Norsk plans to initially print parts in Norway, but is working on a 67,000-square-foot factory with nine printers in Plattsburgh, New York, near the Canadian border.

Traditional automakers have expressed some interest in 3-D printing, with Ford even using some 3-D-printed parts on race cars. But those experiments have largely been limited to prototype parts, not mass-produced ones. Local Motors is still trying to get its 3-D-printed electric car, the Strati, into large-scale production.