We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Whether you bought your first carbureted car or are considering doing so, I want to give you a fair warning. Be ready for every conversation about your ride to involve someone shouting from somewhere that you need to swap to an EFI system. Yes, EFI has its benefits, but that doesn’t mean carburetors are as bad as many would lead you to believe. A well-tuned carburetor can be every bit as streetable and enjoyable to drive as a car with a fuel injection system.

That isn’t to say you won’t need to learn your way around a carburetor, though. As the owner of a classic car, you will need to spend some time under the hood making adjustments to ensure the system is running right.

Don’t worry. You don’t need to be a rocket scientist to set a good baseline. Nor do you need to know the finer points of carburetor theory to keep your historic ride running. Plus, you’re entering the ring with weighted gloves as The Drive’s crack team is ready to set you up with the knowledge you need to get that thing purring like a kitten.

Carburetor Basics

Estimated Time Needed: 30 minutes to one hour

Skill Level: Beginner/Intermediate

Vehicle System: Fuel Delivery

What Is Adjusting a Carburetor?

So, what exactly are we adjusting, and why are we adjusting it? This article is all about making adjustments to your idle mixture and speed. The reason for this is because it’s the one thing that most carburetors have in common. Even if they look different and handle wide-open throttle conditions in various manners, the majority rely on the same basic principles for adjusting idle running conditions—even the methods of making adjustments are very similar.

The primary goal of making these adjustments is to achieve the appropriate engine speed at idle while ensuring it runs as smoothly as possible. In doing so, you’re establishing the proper fuel and air mixture at idle and setting an excellent baseline for further tuning.

Bear in mind that a carburetor supplies air and fuel to the engine differently at idle than it does at wide-open throttle and even part throttle. In short, separate systems and components come into play once you step on the gas pedal. They, too, will need dialing in. But before you get into that, you want to make sure that you have all of your idle adjustments in order as all systems come together to determine how the vehicle behaves in Park or Neutral and what it has to work with as you lean into it.

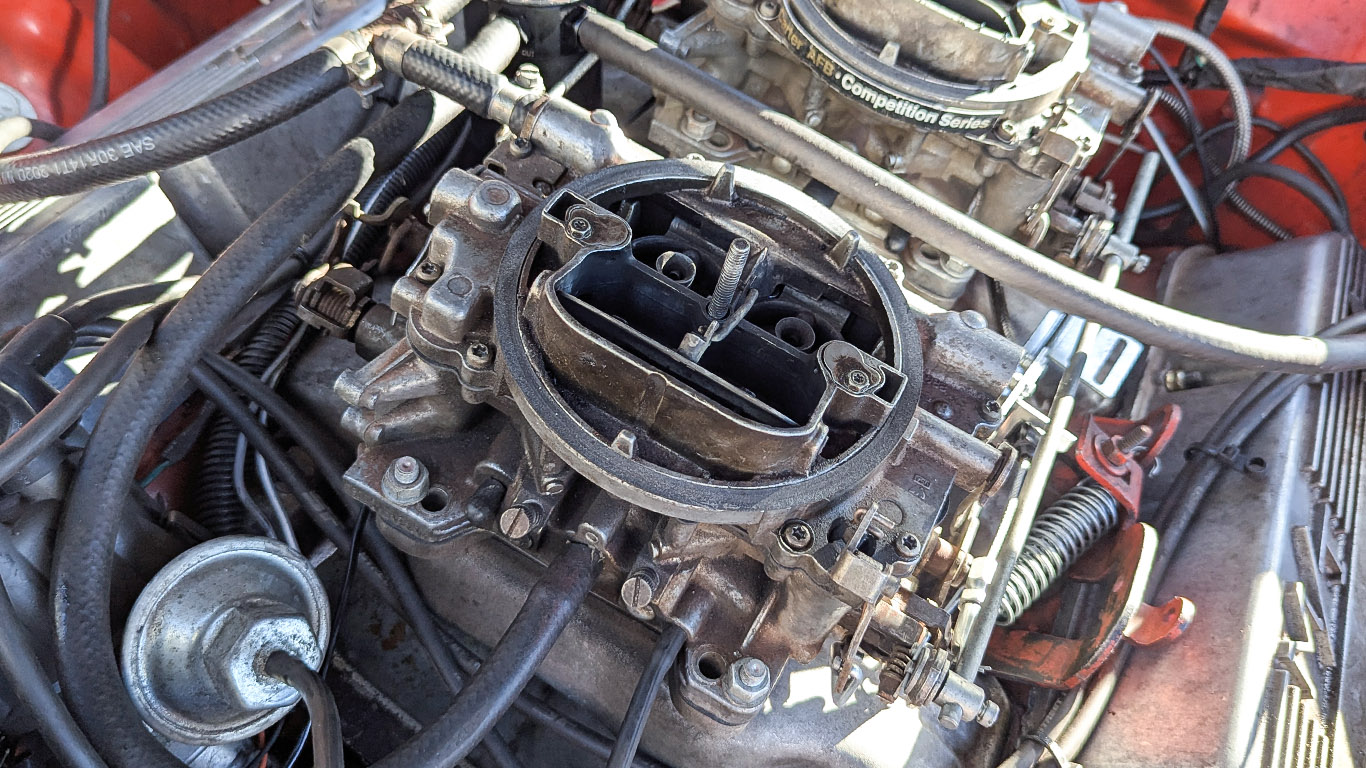

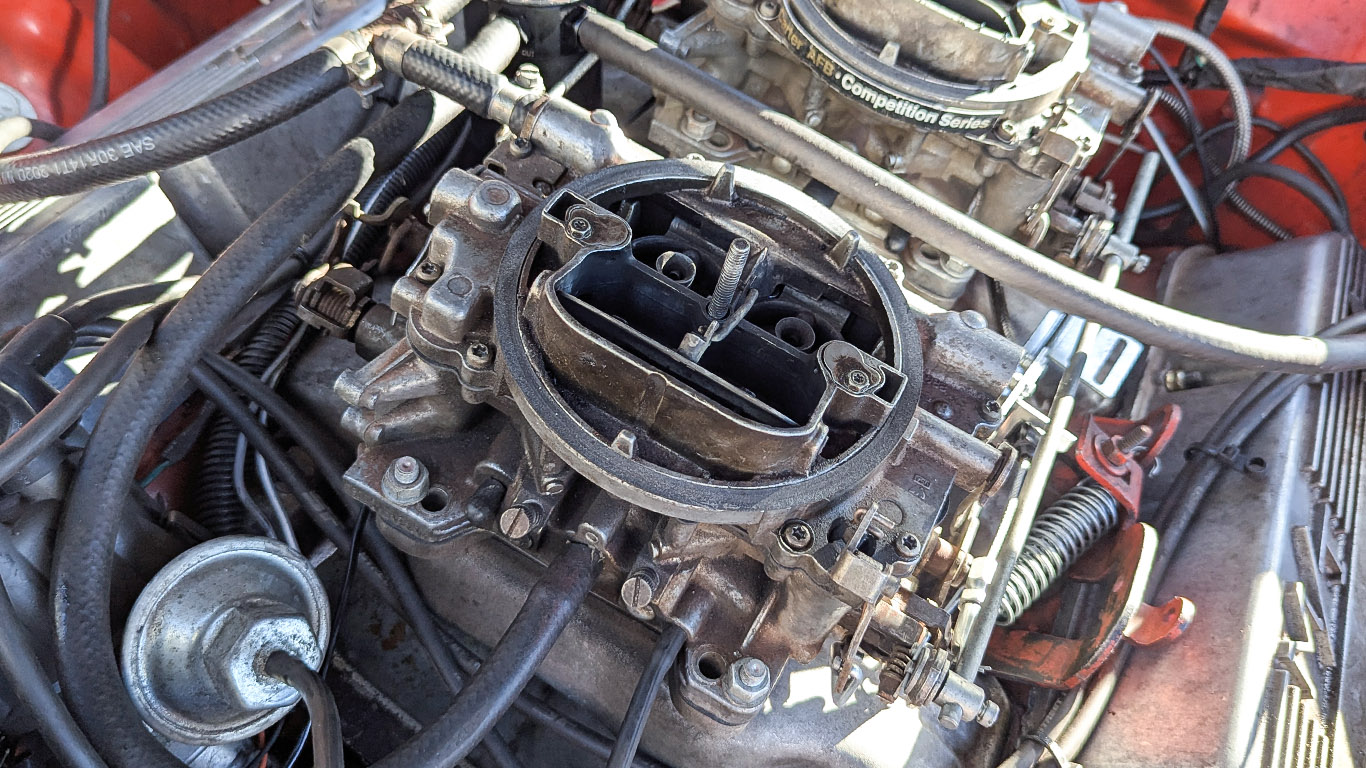

Your means of making these adjustments is with the external idle speed screw and idle mixture screws. Keep in mind the location of these screws will vary with each model of carburetor. You’ll have to do the research to find their exact location on different models. For example, Holley Carburetors typically feature the idle mixture screws on the side of the metering block, while Rochester and Edelbrock’s carburetors feature the idle mixture screws on the face of the carburetor.

The reason that you need to make adjustments is because the carburetor cannot. As temperature, altitude, and even the weather change, so does atmospheric pressure, meaning more or less air is available to the engine. Because the adjustments you make are analog, the amount of fuel going into the engine does not change with the atmosphere. So, you must adjust the carburetor to correct the engine’s running condition at idle. Make sense?

Let’s get into it!

Carburetor Adjustment Safety

Unless you’re setting the baseline, the adjustments you’re making to the carb are performed while it’s running. While the pros never seem to mind, it’s still important to be mindful of the risks before getting started. Be sure to follow these safety tips throughout the procedure.

- Look for fuel leaks. Carburetors are on older vehicles, and there’s always a chance that there’s a fuel leak. If you detect one, make sure to deal with it appropriately before proceeding. Even a tiny backfire is enough to cause a fire with gas on the manifold—ask me how I know.

- Keep your fingers clear of the engine fan. For the most part, you will be working away from the fan. However, there’s always the risk of coming in contact with it and injuring yourself.

- Steer clear of hot surfaces. Some parts of the engine can get hot enough to cause second or third-degree burns. The carburetor itself shouldn’t get anywhere near those kinds of temperatures, but you should still be mindful of hand placement as you work to prevent burning yourself.

- Never place your fingers near or in the opening of the carburetor. As the engine runs, it can backfire, sending a fireball through the carb. The flame and pressure created can cause severe injury.

- You’re working around moving parts and strong chemicals. It is wise to wear a set of safety glasses and protective gloves to keep your skin and eyes intact as you work.

Everything You’ll Need To Adjust a Carburetor

We can’t say what you have on hand, but we can say that you don’t need a lot to make adjustments to your carburetor. In fact, the only tools you really need are a screwdriver and your ears. But, if you’re looking for an easier method that positively determines your engine’s run condition as you tune, you might consider growing your collection.

Tools

- Screwdriver

- Vacuum Gauge (Optional)

- AFR Gauge (Optional)

Organizing your tools and gear so everything is easily reachable will save precious minutes waiting for your handy-dandy child or four-legged helper to bring you the sandpaper or blowtorch. (You won’t need a blowtorch for this job. Please don’t have your kid hand you a blowtorch—Ed.)

You’ll also need a flat workspace, such as a garage floor, driveway, or street parking that’s also well-ventilated. Check your local laws to make sure you’re not violating any codes when using the street because we aren’t getting your ride out of the clink.

Here’s How To Adjust a Carburetor

Let’s do this.

- Remove the Engine Air Filter. The air cleaner and filter assembly must be removed for you to access the carburetor.

- Locate Adjustment Screws. Before beginning, you should familiarize yourself with the location of the idle mixture and idle speed screws.

- (Optional): Hook up Vacuum Gauge. If you are using a vacuum gauge for this process, you should find and connect it to a manifold vacuum port before starting the engine.

- (Optional): Set Baseline. If the carburetor is new or has been rebuilt, you should set it to “factory” adjustment. You can do so by adjusting the idle mixture screws to 1.5-2 turns out, and the idle speed screw to 1-1.5 turns in.

- Warm the Engine Up. The engine’s running temperature directly correlates with proper air and fuel mixtures. So, be sure to let the engine run and reach normal operating temperatures before proceeding.

- (Optional): Adjust Idle Speed Screw. If you set a baseline in step 4, chances are idle is a little high. Be sure to adjust it so that you start with the engine’s normal running speed. You may need to perform this during warm up if the idle speed is too high after reverting to “factory” spec.

- Adjust the Air-Fuel Mixture. Begin by adjusting the idle mixture screws by 1/8 turn increments in or out. Be sure to adjust each in direct relation to the other as you proceed if you have more than one idle screw (most two and four-barrel carburetors do).

- Observe the Engine’s Condition and Continue to Adjust. After each adjustment, give the engine a few seconds to adjust. If it gets rougher or vacuum drops, go the opposite way with the idle mixture screws. If engine speed smooths out or vacuum increases, continue to adjust the screws in the direction you were until it hits the peak engine speed or vacuum.

- Test the Engine at Idle and While Revving. Once peak running condition is met, rev the engine and monitor the condition when the RPM’s drop back to idle. After revving, the idle run condition may change, and you may need to repeat steps 6 and 7.

- Adjust Engine Idle speed. Idle speed will increase as proper adjustments are made. Once you hit peak running condition, adjust the idle speed screw as needed.

Pro Tips for Adjusting a Carburetor

Here are The Drive’s pro-tips on adjusting your carbs.

- Making sure the ignition timing is right is essential to getting your engine in the best run condition. Keep in mind that modern units typically require the timing to be more advanced at idle and you can expect to add a few degrees to initial timing for the best results.

- Don’t make the mistake of assuming that float bowl levels are fine. Any time you make adjustments it is wise to inspect and adjust fuel levels to ensure the engine can perform properly at idle and otherwise.

- Reverting back to factory spec isn’t always necessary, but it can be useful. Especially if you are not familiar with the current running condition or if the carburetor is brand new or freshly rebuilt.

- Even if a carburetor is brand new, it still needs tuning. Your engine, its condition, your location, and the weather all come into play and the carburetor needs to be adjusted properly.

- Adjusting a carburetor is something you perform frequently. It might sound silly but sudden changes in the weather and altitude will impact the way your car runs. As the seasons change or you travel you should adjust accordingly.

- There’s more to tuning carburetors than just adjusting the idle mixture and speed. If you want to improve the performance at part, and wide-open throttle you will need to dive further into tuning the carburetor. This is where things vary by the carburetor and you take a step up from the beginner level of tuning.

- Be mindful of that idle speed screw. If you find yourself having to go more than two turns in to keep the car running, it’s likely that adjusting the idle mixture screws makes no difference. If that’s the case, the carburetor may need a deep cleaning or more advanced tuning steps are necessary.

FAQs About Carburetors

You’ve got questions, The Drive has answers!

A: One way to tell for sure is by “reading” the spark plugs. If the plug tip is white, the mixture is lean. If it’s brown or black, it’s rich. However, this method is usually linked to the carb’s jetting and settings outside of idle, as these colorations come from part and wide-open throttle. At idle, a lean condition will bog down engine speed. If it’s too rich you can generally tell by a strong odor and/or smoke coming from the tailpipe. An AFR gauge is a great tool for getting the precise measurement of these conditions.

A: Simply put, poor running conditions are a dead giveaway. A rough idle, poor throttle response, and excessive fuel consumption are all signs to look for. If the carburetor was sitting for some time or hasn’t been serviced in a while, you may need to clean it first.

A: Adjusting the mixture on a carburetor is done in several ways and the steps ultimately depend on the model of the carburetor you are working with. At idle, however, most carburetors simply require adjustments to be made with idle mixture screws.

A: Ensuring that the carburetor is adjusted correctly is a big step to take when reducing fuel consumption, but it’s not the only thing you can do. Tuning the carb through the RPM range is also essential. Furthermore, because the system is mechanical, you need to practice driving habits that consume less fuel.

A: The best method to check air-fuel ratios is with an AFR gauge. Tuning by ear or with a vacuum port are effective ways to determine running condition, but don’t actually read the air-fuel ratio. AFR gauges use an O2 sensor, just like modern cars, to provide an accurate and real-time reading. If they are within your budget, these tools are worth investing in for carb tuning.

Learn More With This Video about Carb Adjustments

Featured Products

WD-40 – 300134 Specialist Carb/Throttle Body & Parts Cleaner