Best Plasma Cutters: Slice Through Metal Quickly and Easily

Cut or create your own metalworks with these high-quality plasma cutters

We may earn revenue from the products available on this page and participate in affiliate programs. Learn more ›

Designed to cut through thick and tough metals, plasma cutters are best suited for machine shops and heavy-duty construction applications. They rapidly heat up with compressed air or gas, and the arc torch is capable of reaching extremely hot temperatures. The small flame is then able to make a clean cut through tough metal and steel with ease. If you have a difficult job and need a high-quality plasma cutter, consider one of the following machines for your workshop.

Lotos 50Amp Non-Touch Pilot Arc Plasma Cutter

Zeny DC Inverter Plasma Cutter

Cut-50, 50 Amp Pro Plasma Cutter

Summary List

- Best Overall: Lotos 50Amp Non-Touch Pilot Arc Plasma Cutter

- Best Value: ZENY DC Inverter Plasma Cutter

- Best Industrial Grade: Cut-50, 50 Amp Pro Plasma Cutter

- Premium Pick: Hypertherm Powermax 30 XP Plasma Cutter

- Honorable Mention: Forney Easy Weld 20 P Plasma Cutter

- Honorable Mention: Lotos LTPDC2000D Non-Touch Pilot Arc Plasma Cutter

- Honorable Mention: Everlast 2020 PowerPlasma 62i 60 Amp Plasma Cutter

Best Plasma Cutters: Reviews & Recommendations

In order to penetrate the world of plasma cutting, Lotus has been creating affordable machines that do a great job. This reasonably priced machine continues with that tradition by delivering 50 amps and a 60-percent duty cycle. We love the pilot arc feature that allows you to cut without joining the tip to the metal. The Lotos LTP5000D uses non-hazardous compressed air. It cuts a variety of materials, including aluminum, copper, mild steel, alloy steel, and stainless steel.

This is one of the best plasma cutters in the 110V/220V range. It can cut through rusty, painted, and rough surfaces and produces minimal slag. With a cutting range of 10-50 amps, it can perform 1/2-inch clean cuts and 3/4-inch maximum severance cuts under 220/240V. PAPST Advanced Cooling Technology ensures its performance is stable. The plasma cutter also features a pre-installed air filter regulator and a type D plug.

The Lotos LTP5000D is ideal for DIY jobs or light-duty cutting projects. It weighs less than 20 pounds, so it's not too hard to carry around. However, it has a few shortcomings. First, slag may accumulate on the tip, making it slow down or stop. Second, the compressed air line is quite small.

Plasma cutters are designed to cut through materials that conduct electricity. These machines are efficient and have the ability to cut a variety of metals. The Zeny DC Inverter Plasma Cutter can cut materials as strong as alloy steel. Its high-quality plasma torch is specially designed to enhance and improve the cut quality. The machine has a built-in inverter that generates powerful DC welding current.

If a dual-voltage direct current plasma cutter is what you need, this machine is worth looking at. It has the ability to operate at 110 volts or 220 volts. It can also supply gas beforehand and turn off automatically when gas dispensation is delayed. This plasma cutter is ideal for a wide range of applications, including automotive ducting work, light industrial work, sheet metal fabrication, and repair and maintenance services. This unit is highly portable as it only weighs 24 pounds. It has a carrying handle for enhanced portability. We also like the pilot arc striking system, which makes it easy to start.

However, this plasma cutter has a few downsides. Zeny provides complicated instructions that are hard to understand. The air regulator is also not very well designed and may affect the arc's power.

What impresses us about this plasma cutter is not just its price but the fact that it has so many great features. It automatically adapts from 100V to 240V input power, and its torch design ensures it provides a clean cut every time. Its hand grips are made from heat-resistant and impact-resistant material. The machine is designed for demanding construction or industrial projects, but it can also be used at home.

Amico's CUT-50, 50-Amp Pro. Plasma Cutter can cut stainless steel, copper, aluminum, mild steel, alloy steel, and a variety of other materials. It can cut up to one-inch-thick metals. Amico recently upgraded this model, so it now has the meter and adjustment at the front while the filter is located inside it. Its new design makes it easier to use. The 50-amp plasma cutter also has an inverter that allows for a high-frequency start. You don't have to place the tip of the torch on the metal to cut it. This plasma cutting machine has a gauge that lets you read and control the temperature more effectively.

Unfortunately, it is on the heavier side (it weighs 31 pounds), so you may not be able to carry it around very easily. It is also not very durable.

Hypertherm is a unique company because all it sells is cutting technology. Unlike the other companies whose products we have listed, it does not manufacture welding machines. It specializes in plasma cutters, laser cutters, and water jets. Hypertherm has been creating high-quality plasma cutters since 1968, and most of its machines have been very well received.

The Hypertherm 088079 Powermax30 XP is one of the best cutters for home use and has all the features a DIYer may need and more. While the machine is not able to engrave like the Powermax 45XP, it can easily sever a 5/8-inch metal plate and give cut surfaces pristine edges. The cutter has a 110V/240V power input and uses nitrogen or air to cut electrically conductive metals such as aluminum and stainless steel. We also love the 15-inch torch lead that makes plasma cutting a much better experience. Drag Cutting Technology makes for easy tracing and also ensures that no double arcing occurs. We are highly impressed with this plasma cutter. The design of the torch provides a comfortable grip, and it is made from heat-resistant and impact-resistant material.

One downside is that the machine's internal air valve may leak if it is heavily used in an industrial setting. And unlike some top-of-the-range plasma cutters, it lacks a CPC port for computer control.

If you're looking for a high-quality plasma cutter and are on a budget, this one is worth considering. As plasma technology keeps on advancing, many companies keep refining their processes to produce better, more affordable machines. Forney's Easy Weld cutting machine is a good example of that endeavor. It is exceptionally made and cuts well. If you use it to cut any metal that is 1/4-inch or less, it will cut it with almost no effort.

We really like the size of the torch and the clamp lead as it's more than enough for most people. If you want to add diversity to this welder, you can get the extensions that are sold separately. The machine has a pilot arc with a high-frequency start and is easy to use. Drag Torch Technology creates smooth, precise cuts because you can drag the tip on the surface of the metal. The Forney Easy Weld cutting machine is a good option for experienced operators who cut 1/4-inch metals on a regular basis. Metals that are usually this thick include galvanized steel, stainless steel, copper, and brass.

However, while this machine can cut painted or rusty metal, it doesn't cut it very well. It is also greatly limited by its 110V/120V input and 20-amp output and will struggle to cut any metal that's over 1/4-inch. If you don't cut any metal thicker than this, it's a good option.

Anyone who has ever worked with metal will tell you that making precise cuts with conventional metal cutters is no joke. Poor cuts affect how the final products look like, especially the finish and the fit. If your job involves cutting steel sheets of different sizes and shapes, get the Lotos LTPDC2000D. It is a three-in-one cutting machine that can also be used as a stick welding machine or a TIG welding machine.

Its pilot arc torch quickly cuts through painted, rusty, and rough surfaces, producing minimal slag. It increases precision and decreases material wastage. Automatic dual voltage allows the Lotos LTPDC2000D to turn on directly on 110V/120V at 50/60 Hz power.

This cutter has one great safety feature. It can use machine-compressed air, which means you don't have to carry pre-compressed air in cylinders. It can make clean cuts on metals that are 1/2-inch thick. The maximum severance thickness is 3/4-inch. Pilot Arc Technology lets you cut metals without touching the torch’s tip to the metals. This cutting machine comes with a 30-day money-back guarantee and a one-year limited warranty. You can buy it with confidence.

However, the guide is not well-built and slides on the cup. If you are a novice, you will find it very difficult to maintain distance and may end up destroying the nozzle and electrode. Additionally, the consumables for the machine are specific and do not come cheap

Everlast designed the PowerPlasma 62i to replace the PowerPlasma 60S. It features BlowBack Pilot Arc Starting, which makes it easier to use on materials with rust and paint. You will also love its super bright control displays that are easy to read even when you're wearing safety gear and the environment is filled with bright light. You’ll be hard-pressed to find a plasma cutter with the same features in this price range. It has a 60-percent duty cycle at 60 amps.

Everlast includes an automatic pressure setting in this cutting machine. It adjusts the pressure during the cutting process for a clean cut. The three-second tip timer quickly turns off the torch if no cutting is going on after three seconds of arc time. This new model has a gouge feature for cutting out old welds and metal defects. This feature is quite unusual for cutting machines in this price bracket. You'll be pleased by the digital arc control that helps maintain the best cutting temperature for clean cuts.

However, there is an issue with this machine's power. If you want to power this cutting machine using a generator, you need one that produces at least 11,000 watts of clean power. If you don't and the machine gets damaged, the warranty will be voided. But it’s not easy to get a generator that produces that much clean power. The machine is also heavy and not very portable.

Our Verdict on the Best Plasma Cutters

For one of the most powerful and precise plasma cutters, consider the Lotos 50Amp Non-Touch Pilot Arc Plasma Cutter.

You can get the Zeny DC Inverter Plasma Cutter, which provides a clean and smooth cut at a much cheaper price.

Benefits of a Plasma Cutter

- Eliminates plate warping. A high definition plasma cutter has a fast cutting speed and significantly reduces the amount of heat transferred to the material. It prevents plate warping of thin materials (18-gauge to 1/4-inch). This issue commonly occurs when a conventional plasma cutter is used.

- Faster cutting speeds. When a high definition plasma cutter is used to cut metal up to two inches thick, it cuts it twice as fast as an oxyfuel cutter. The thinner the metal is, the faster it will cut it. A plasma cutter can cut thin metals up to 12 times faster than a traditional cutter. When you are able to cut more parts in less time, your productivity increases.

- Reduced dross. Oxyfuel cutting creates dross (an oxide slag) because of the chemical reactions between oxygen and steel. In order to be removed, the consolidated dross must be chiseled or grounded. But since a high definition plasma cutter uses electrically-charged, high-temperature gas, it melts metal, blowing the molten metal away from the cut. Grinding or chiseling is not necessary as any extra metal is gotten rid of.

- Versatility. A plasma cutter uses an electric arc process and can cut any material that conducts electricity. It can cut aluminum, copper, stainless steel, and non-ferrous materials. It can also cut a stack of metal plates. Oxyfuel cutters can't do this.

Types of Plasma Cutters

Conventional Plasma Cutters

Conventional plasma cutters utilize air, oxygen, or nitrogen for cutting. They are more affordable than high definition plasma cutters and produce quality cuts. However, the cut surface will have an angle. The ratio of the minimum hole quality to plate thickness is 3:1. Most conventional plasma cutters operate at 65 amps to 200 amps. They are mostly used to cut mild steel. Conventional plasma cutters are typically used for home garage fabrication to midsize production. They are ideal for simple cuts or cuts that do not require intricate edges.

High Definition Plasma Cutters

High definition plasma cutters are useful where more intricate cutting is required or where the edge quality is of concern. They utilize a blend of gases and have smaller nozzles. The nozzle helps tighten the plasma stream, allowing you to cut parts more intricately. One gas in the blend acts as a shield and covers the plasma stream, keeping it straighter. Since a high definition plasma cutter has a more directed stream, it does not create consolidated dross on the cut. This does away with grounding and chiseling. A high definition plasma cutter is ideal for more demanding applications. It has a higher duty cycle and can run for 24 hours a day.

Plasma Cutter Pricing

- Under $500: These plasma cutters get the job done but do not have ergonomic designs or useful add-ons. They are ideal for occasional users

- $500-$1000: These plasma cutters do not have the best duty cycle or amperage rating. They may be controllable but lack good cutting capacity.

- $1000-$2000: The best plasma cutters cost between $1,500 and $2,000. They have all the features you may need for enhanced productivity, like inverters and excellent cutting capacity.

Key Features

Cutting Speed

This is a very important feature to look at. The thickness of the metal usually determines the cutting speed. Before you get a plasma cutter, it is important to compare the cutting speed to the thickness of the metal. There are three cutting standards: quality cuts, rated cuts, and severe cuts. A cutter with a quality cut rating takes a while to cut thicker materials. One with a rated cut rating cuts medium-thick steel at optimal cutting speed. A plasma cutter with a severe cut rating can cut very thick materials slowly.

Duty Cycle

This is another important feature to consider. The amperage usually determines the duty cycle of a plasma cutter. For example, a plasma cutter with high amperage output will have a better duty cycle than one with a low amperage output. If you want a plasma cutter that you can use continuously for long periods, buy one based on the thickness of the materials you usually deal with. Also check the maximum severance thickness.

Input Power

In order to work efficiently, plasma cutters need a high amount of electricity. They are usually designed to pull power from 110-volt or 220-volt power outlets. Every cutting machine has an amperage rating. Check the voltage of the power outlet to be used to ensure it can meet the minimum amperage requirements of the plasma cutter. It is also important to have a different circuit for your plasma cutter because when other machines are connected to the same circuit, the input power to your machine is reduced.

Air Supply

Most handheld plasma cutters use air for the cutting process. Some professionals use bottled nitrogen for cutting because it is less expensive than bottled air. They also believe that nitrogen produces less oxidation because it is drier than compressed air. Some cutting machines have built-in air compressors, which means you don't have to carry bottled gas around.

Other Considerations

- Built-In Inverter. If you mostly work in remote sites where there is no access to power, it makes sense to get a plasma cutter with a built-in inverter. It is more expensive than other plasma cutters but will continue working even when there is no electricity available. Most plasma cutters with built-in inverters are portable

- Type of Start. To initiate a pilot arc, a plasma cutter can either use a contact start or a high-frequency start. If you'll be using your machine near electronic devices such as computers, get a plasma cutter with a contact start. A unit with a high-frequency start will affect the functioning of the electronic appliances. A plasma cutter with a contact start also allows you to position the torch more accurately because it creates a visible pilot arc.

Tips

- Make sure the power source you are plugging the plasma cutter into can handle the machine. If not, you may end up tripping a breaker and shutting off the power.

- Wear protective eyewear to avoid any slag or other debris from getting in your eyes.

- Always wear a thick pair of gloves when operating the cutter. They will ensure your hands don’t get dangerously burned. Always use caution when operating it, and do not get your body close to the arc.

- It will get hot when operating a plasma cutter, so you will want to ensure you have someplace to cool down if you get overheated.

- Always make sure the plasma cutter is turned off when you are finished using it and any metal is removed from beneath the torch. The pilot arc will take time to cool down and may warp or bend the metal if it’s left unattended.

FAQs

Q: What do I need for a plasma cutter to function?

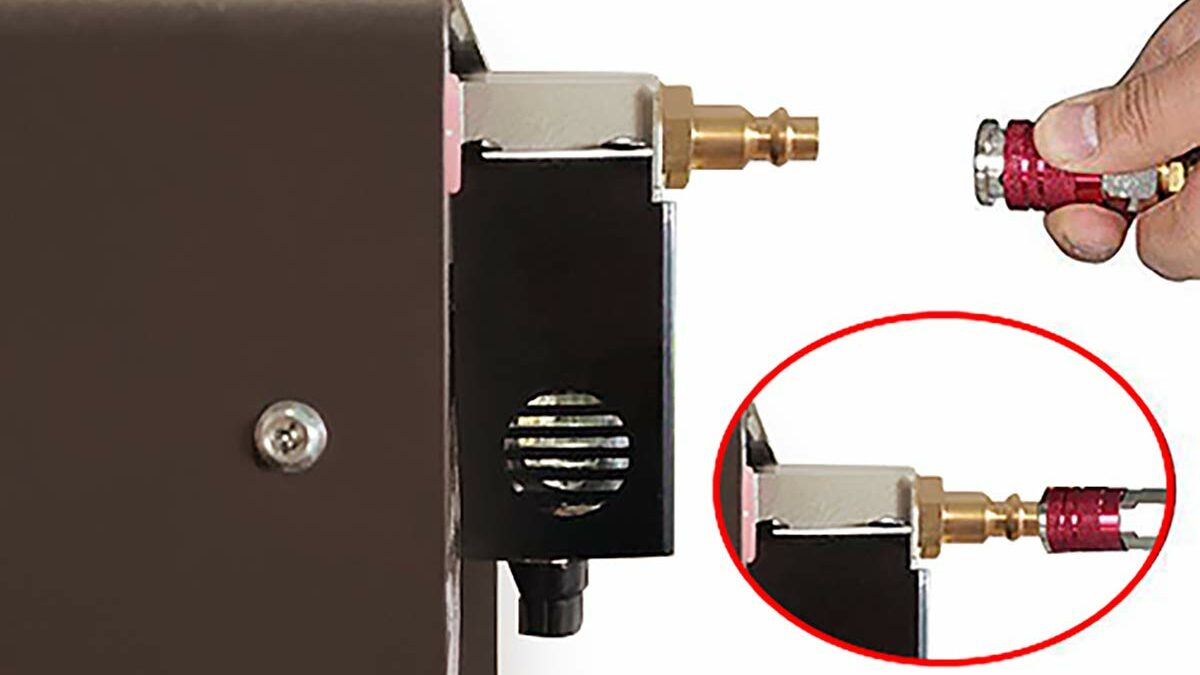

A: You will need a reliable and functional air compressor and air hose to ensure the plasma cutter works properly. Many may not come with a plug for the air hose, so you will need to check with the manufacturer before buying a plasma cutter.

Q: How hot can a plasma cutter get?

A: Since it is made for cutting thick steel and metals, the pilot arc will reach extremely dangerous temperatures. Use caution when handling a plasma cutter as they can reach temperatures of up to 45,000 degrees Fahrenheit.

Q: How long will it take to cut a piece of metal?

A: It depends on what you are cutting and how you want to cut it. If you just need to slice one piece it shouldn’t take more than a few seconds. If you are making small precise cuts, then it can take a few minutes. Always work slowly and methodically to make sure you stay safe.

Why Trust Us

Our reviews are driven by a combination of hands-on testing, expert input, “wisdom of the crowd” assessments from actual buyers, and our own expertise. We always aim to offer genuine, accurate guides to help you find the best picks.

Learn more